Introduction

In industries where air purity is critical—such as food processing, pharmaceuticals, electronics, and healthcare—the presence of oil in compressed air can lead to product contamination, equipment failure, and compliance risks. Traditional lubricated compressors, while effective for general use, fall short in these sensitive environments. This is where an oil free air compressor becomes essential. By providing 100% contaminant-free air, these systems eliminate the risk of oil-related issues while offering enhanced efficiency and lower long-term maintenance costs. For factory procurement managers, engineers, and distributors, understanding the technical advantages and applications of oil-free technology is key to optimizing operational reliability and sustainability.

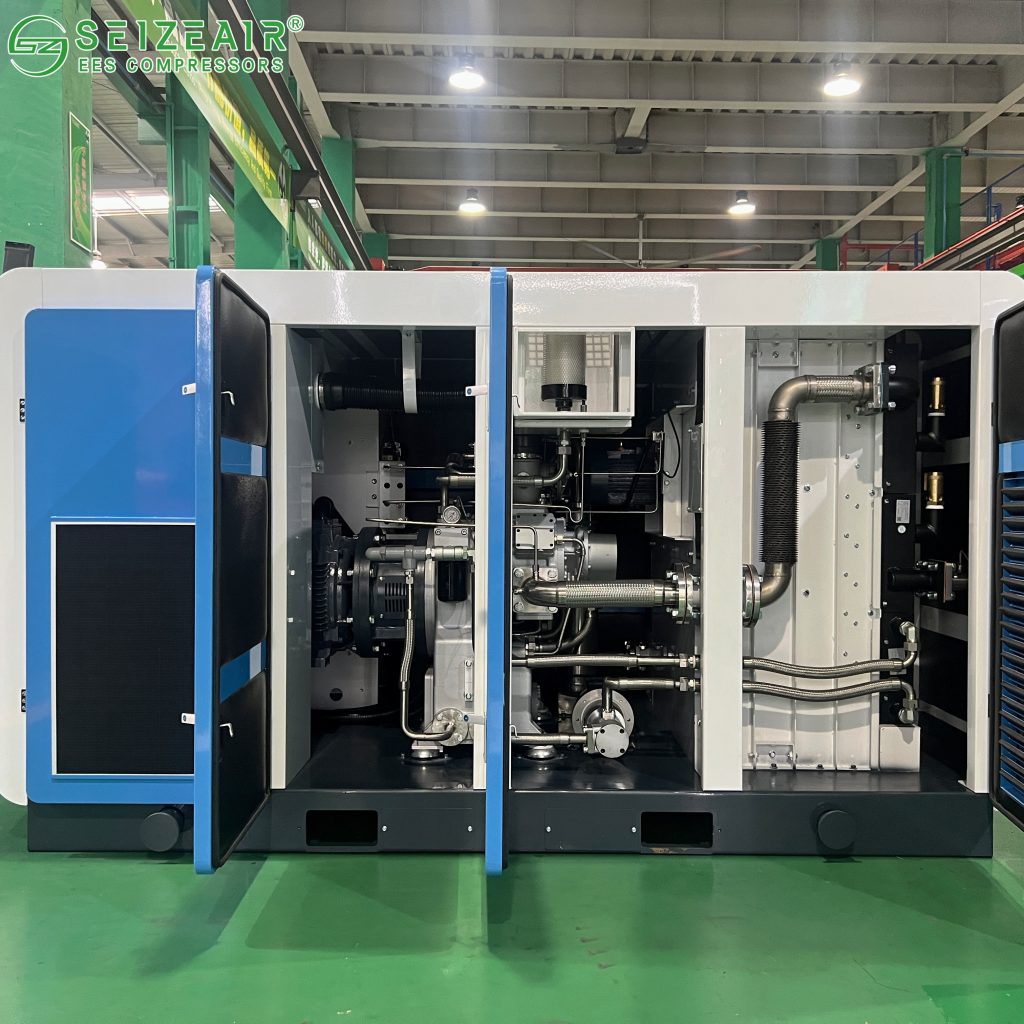

1. How Oil-Free Air Compressors Work: Technology and Design

Unlike lubricated compressors, oil-free models operate without oil in the compression chamber. They use advanced sealing mechanisms, such as water-injected or dry screw elements, alongside coatings like PTFE or molybdenum disulfide on rotors to reduce friction. This design ensures zero oil carryover, meeting ISO 8573-1 Class 0 standards—the highest certification for air purity. For industries such as pharmaceuticals or semiconductor manufacturing, this ensures compliance with stringent hygiene regulations. Additionally, the absence of oil eliminates the need for oil filters and separators, simplifying maintenance and reducing operational costs.

2. Key Advantages of Oil-Free Compressors

- Zero Contamination Risk: Essential for industries where air purity directly impacts product quality, such as medical device manufacturing or beverage bottling.

- Reduced Operating Costs: With no oil changes, filter replacements, or oil disposal expenses, long-term upkeep is reduced by up to 30%.

- Energy Efficiency: Modern oil-free units integrate permanent magnet variable frequency drives (VFDs), adjusting output to demand and saving 20–40% in energy consumption.

- Environmental Compliance: Avoids hazardous waste generation, supporting ESG goals and reducing regulatory burdens.

3. Applications Across Industries

| Industries | Applications |

| Food & Beverage | Prevents oil-induced spoilage in packaging and processing. |

| Pharmaceuticals | Ensures sterile air for drug production and laboratory environments. |

| Electronics | Protects sensitive components from oil aerosols during manufacturing. |

| Power & Cement Plants | Critical for instrumentation air where oil-free air prevents valve clogging and system failures. |

4. Choosing the Right Oil-Free Compressor: A Procurement Checklist

- Air Quality Standards: Ensure ISO Class 0 certification and compliance with specific industry requirements.

- Capacity & Pressure Range: Match the unit’s free air delivery (FAD) and pressure to operational needs.

- Cooling System: Water-cooled models are ideal for high-ambient-temperature regions (e.g., Middle East), while air-cooled versions offer more flexibility.

- Total Cost of Ownership: Factor in energy consumption, maintenance intervals, and lifecycle durability.

5. Maintenance Tips for Long-Term Reliability

Although oil-free compressors require less upkeep, proactive measures are crucial:

- Regularly inspect air filters to prevent dust ingress in arid or dusty environments.

- Monitor cooling systems to prevent overheating, especially in high-temperature settings.

- Use IoT-enabled controllers for real-time alerts on performance deviations.

Conclusion

An oil free air compressor is not just an upgrade—it’s a strategic investment for industries focused on air purity, efficiency, and compliance. By eliminating oil-related risks and reducing lifecycle costs, these systems help businesses maintain high operational standards. Seize Air, a leading Chinese manufacturer, specializes in energy-efficient, oil-free screw compressors, combining reliability with advanced engineering. Whether upgrading existing systems or deploying new solutions, Seize’s commitment to innovation ensures your operations remain clean, efficient, and future-ready.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch