Methods of Energy Saving in Air Compressor Systems: A Practical Guide

Introduction Compressed air systems are a major energy consumer in industrial settings, often accounting for up to 40% of a factory’s total electricity costs. By adopting effective energy-saving methods in air compressor systems, companies can achieve significant cost savings while boosting overall operational efficiency. In this guide, we’ll explore practical…

Read MoreCompressed Air in Food Manufacturing: Non-Negotiable Requirements

The global Food Manufacturing, valued at $4.1 trillion in 2024, relies on compressed air for 80% of automation processes – from bottling lines to pneumatic slicing. However, air quality failures can lead to: FDA recalls (23% linked to contaminated compressed air in 2023) Bacterial growth from moisture/oil residues Line shutdowns costing $10,000+/hour Seize…

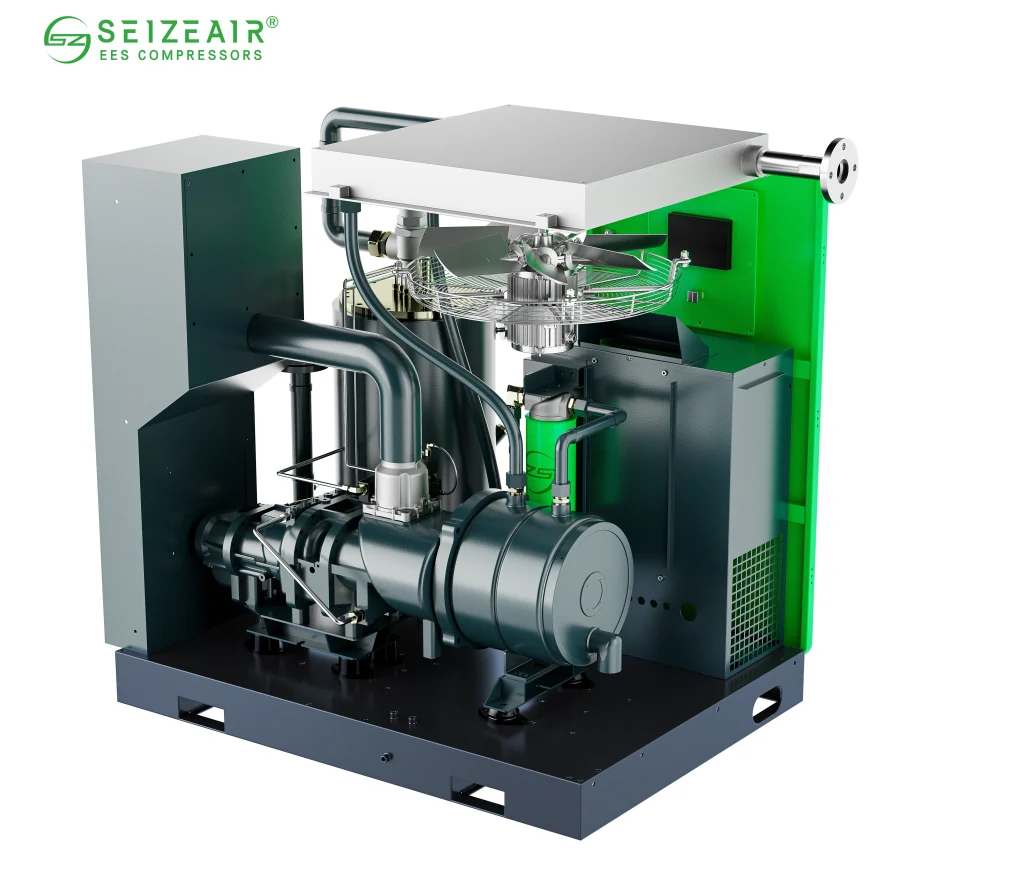

Read MoreOptimizing Industrial Air Supply: The Comprehensive Guide to oil free air compressor

In sectors where air purity is non-negotiable, such as pharmaceuticals, food and beverage processing, and electronics manufacturing, compressed air must meet the highest standards. The risk of even trace amounts of oil contamination is a major concern, as it can directly lead to product spoilage, damage sensitive equipment, and cause…

Read MoreEnergy Saving Air Compressor: A Smart Investment for Industrial Efficiency

Introduction In today’s industrial landscape, energy costs account for a significant portion of operational expenses, with traditional air compressors often being a hidden culprit. Known as “electricity tigers,” these machines can consume excessive power, driving up costs unnecessarily. The solution? Energy saving air compressors—advanced systems designed to reduce electricity consumption by…

Read MoreComprehensive List of Common Air Compressor Fault Codes: Quick Diagnosis and Solution Guide

As one of the most critical pieces of industrial equipment, air compressor failure can directly affect production efficiency and costs. With proper air compressor maintenance, technicians can quickly identify fault codes, minimize downtime, and keep operations stable. This guide provides a detailed overview of the most frequent air compressor fault…

Read More

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch