Under the pressure of carbon reduction targets and the need to improve operational efficiency, factories are shifting away from traditional air compressors in favor of energy-efficient models. This transition is not just about environmental responsibility—it’s also a smart financial move.

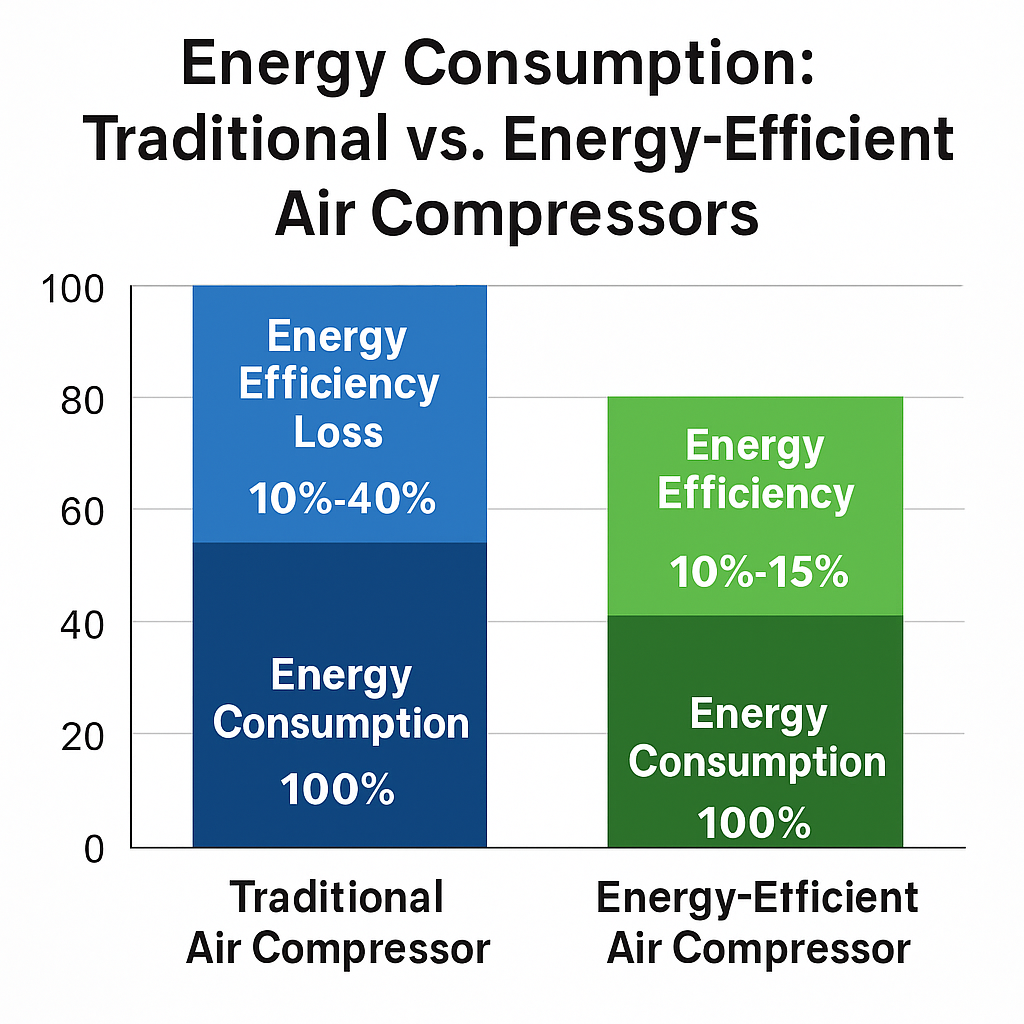

Traditional air compressors are notorious for their inefficiency. In fact, air compression systems account for 10% to 35% of industrial electricity consumption, and traditional equipment can lose 30% to 40% of that energy through outdated designs. In contrast, modern compressors with permanent magnet variable frequency technology dynamically match output with demand, cutting power consumption by 30% to 50%.

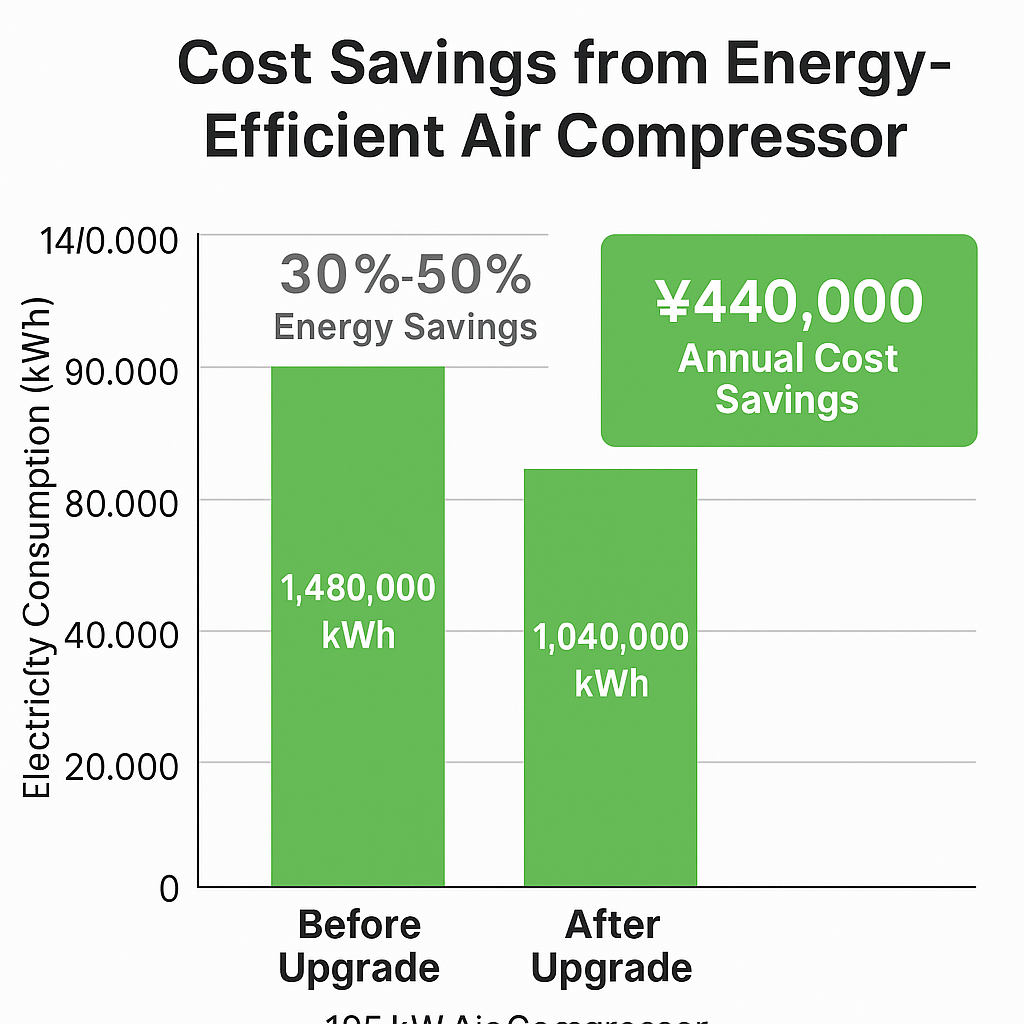

For example, a 185kW compressor operating annually can consume 1.48 million kWh. By switching to a high-efficiency model, a factory can save up to ¥440,000 per year, with a payback period under one year. These kinds of savings are too significant for industrial operators to ignore.

Cost Savings, Compliance, and Intelligent Upgrades

The first driver behind this shift is energy cost pressure. Older machines often run at low or no-load states, wasting up to 45% of energy due to fixed-speed operations and over-sizing. Newer energy-efficient compressors address this problem by adjusting output to actual demand, drastically reducing waste.

A second major factor is regulatory pressure and government incentives. Equipment with a specific power consumption greater than 7.5kW/(m³/min) is being phased out in many markets. Governments are offering subsidies for first-class energy-saving equipment, and every 1kWh of electricity saved reduces 0.785kg of CO₂ emissions, contributing directly to sustainability goals.

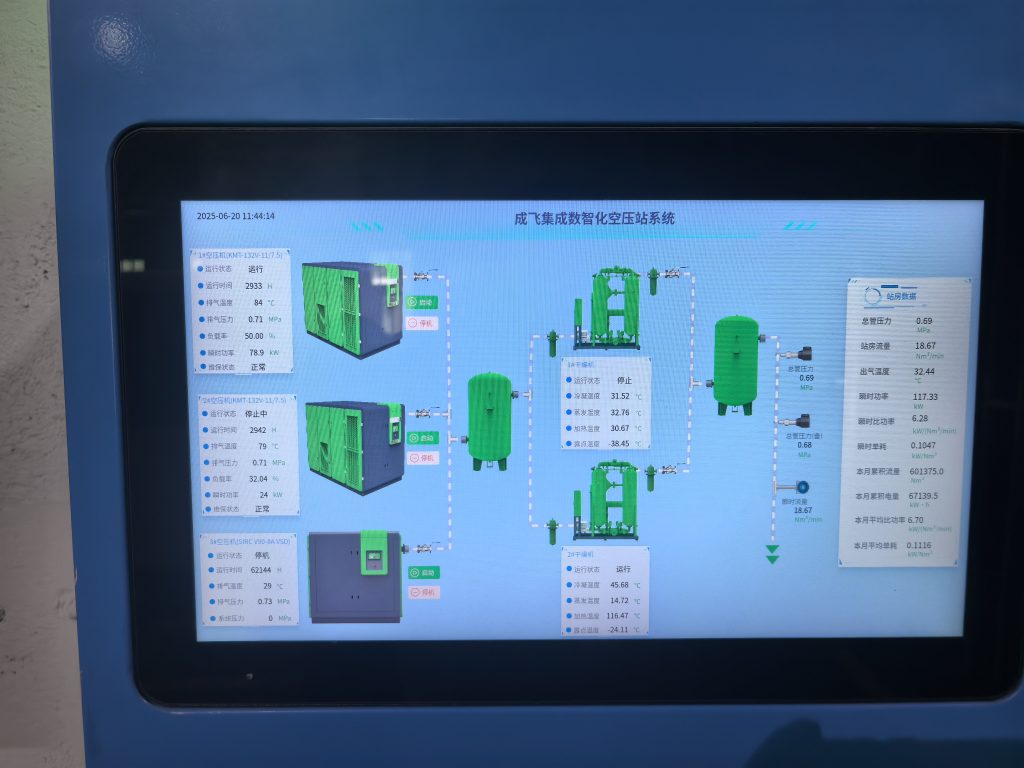

Beyond compliance and costs, system efficiency and long-term value are also key. Intelligent control systems, such as AI-powered optimization and waste heat recovery, allow energy utilization rates to reach 85%. These technologies also lower operation and maintenance costs by up to 30%. With energy performance contracts (EMC), companies can pay for equipment upgrades through the savings they generate—zero upfront investment, long-term gain.

How to Select the Right Energy-Efficient Air Compressor

Step 1: Understand Your Application Needs

1.1 Determine Air Volume and Pressure

- Air Volume (m³/min): Choose based on average and peak demand to avoid over-sizing.

- Pressure (MPa): Match your specific use case. For example:

- Spraying equipment: 0.7–1.0 MPa

- Pneumatic tools: 0.6 MPa

1.2 Consider Air Quality

- Oil-free compressors (ISO 8573-1 CLASS 0) are essential for pharmaceutical and electronics industries.

- Oil-injected models are suitable for general industrial use.

1.3 Analyze Runtime

- If your system operates over 16 hours/day, opt for permanent magnet VFD models.

- For intermittent usage, traditional industrial frequency models may suffice.

Step 2: Select the Right Compressor Type

2.1 Permanent Magnet Variable Frequency Screw Compressors

- Energy Efficiency: Specific power ≤ 5.9 kW/(m³/min)

- Savings: Up to 50% energy savings with fluctuating loads

- Technology Highlight: Two-stage compression increases efficiency by an additional 15%–20%

2.2 Centrifugal Compressors

- Best for large air volume needs (>100 m³/min) with stable loads

- High efficiency, but comes with higher upfront costs

2.3 Oil-Free Models

- Necessary for industries with strict cleanliness requirements

- Typically lower energy efficiency and higher cost—balance is needed

Why Seize Air is the Preferred Choice

Seize Air has emerged as a leader in energy-efficient air compressor technology. Its self-developed twin-screw and two-stage compression systems bring 12%–15% energy savings over traditional single-stage compressors, with an additional 5%–8% from the dual-stage design. With permanent magnet frequency control, pressure stability is kept within ±0.1 bar, ensuring consistent performance.

Their oil-free compressors are ISO 8573-1 CLASS 0 certified, and feature low-noise design, reducing sound levels to 60–75 dB—about 20% quieter than the industry average.

Seize Air’s success is backed by market recognition: it has been ranked #1 in China’s air compressor brand rankings for five consecutive years, sold over 30,000 units in 2025, and helped reduce 15 million tons of carbon emissions globally. The company holds 90+ patents, including 10+ invention patents, and has earned titles like “Energy Efficiency Star” and green technology certification in Shanghai.

Real Industry Results and Case Studies

Factories across industries are already seeing major returns. A textile plant in Zhejiang saved 120,000 kWh annually, reduced noise from 85 dB to 60 dB, and cut maintenance costs by 60% after switching to Seize Air. In lithium battery production, a customized compressor system reduced total energy consumption by 30%. A photovoltaic facility reported an energy efficiency improvement of 25%–35% after adopting Seize Air’s integrated solutions.

These results are supported by Seize Air’s nationwide service network of over 200 service outlets, with 2-hour response time and 24-hour on-site support. The “Seize Air Cloud” platform enables remote monitoring and early failure detection—one food manufacturer avoided costly downtime by preemptively replacing worn parts.

Long-Term Support, Real Customer Satisfaction

Seize Air also offers a 10-year warranty on compressor hosts—an industry rarity—backed by 100% in-house R&D on core components. With 99% on-time maintenance rates, nationwide parts availability, and a team of highly trained engineers, Seize Air ensures stable operations and long-term peace of mind.

Customer reviews say it best:

“We’re saving nearly ¥10,000 per month in electricity after switching to Seize Air. The long warranty gives us confidence.”

— Manufacturing company, Jiangsu

“Our Seize Air compressor has run 8,600 hours non-stop without failure, saving us ¥150,000 a year.”

— Petrochemical enterprise

Conclusion: Choose Seize Air, Choose Sustainable Growth

With powerful technology, proven cost savings, and reliable service, Seize Air’s energy-efficient compressors are a smart investment for any factory looking to cut emissions, reduce operating costs, and future-proof its operations.

Choosing Seize Air means choosing smart, green, and profitable industrial transformation.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch