From August 7 to 9, 2025, the prestigious Shanghai Biofermentation Technology and Equipment Exhibition (BIO-FERMENTATION TECH 2025) was held at the Shanghai New International Expo Center. As a leading name in China’s energy-efficient air compressor industry, Seize Compressor (Shanghai) Co., Ltd. made a remarkable appearance, showcasing its full lineup of oil-free, energy-saving air compressor solutions tailored for the biotechnology and fermentation sectors.

Meeting the Demands of the Biotechnology Fermentation Industry

At the exhibition’s opening, Mr. Yang, General Manager of Seize Air’s New Energy Division, delivered a keynote speech titled “Compressed Air System Solutions for the Biopharmaceutical Industry.” He emphasized:

“Compressed air quality requirements in modern biotechnology fermentation have reached unprecedented levels. For fermentation plants with annual output values around 1 billion yuan, compressed air systems can consume 25%-30% of total energy — even small fluctuations in air quality can affect entire production batches.”

Extensive surveys of over 300 biopharmaceutical companies helped Seize Air identify key industry challenges:

- Oil contamination risks: Traditional lubricated compressors risk oil entering fermentation air systems

- Moisture control: Moisture can disrupt culture medium osmotic pressure, impacting microbial activity

- Pressure instability: Fluctuations affect dissolved oxygen, disrupting microbial metabolism

- High energy consumption: Continuous 24/7 operation leads to significant electricity costs

Innovative Solutions on Display

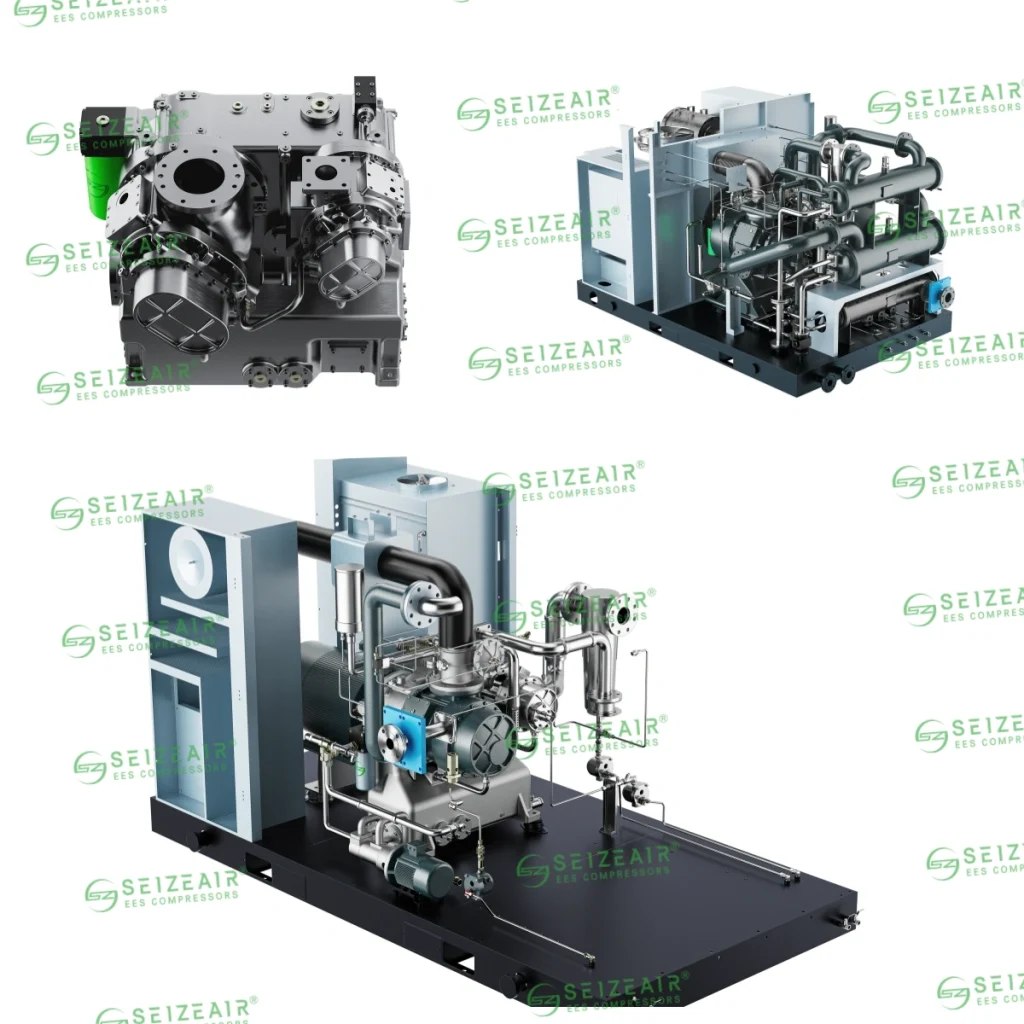

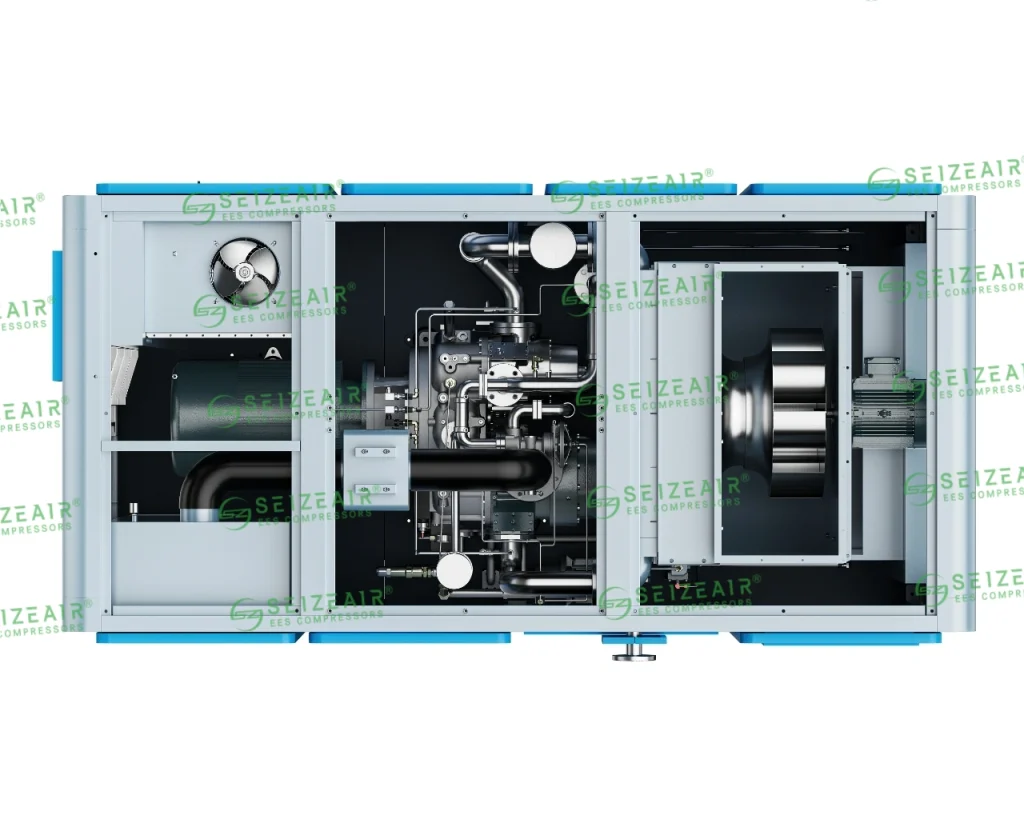

Seize Air debuted three cutting-edge product lines designed to overcome these pain points:

1. Permanent Magnet Variable-Frequency Oil-Free Screw Compressors

- German-imported two-stage compression unit improving efficiency by 15%

- TÜV-certified 100% oil-free sealing technology

- Intelligent variable frequency control delivering 35% energy savings

- Modular design cutting maintenance time by 50%

- The on-site SVOW-110A model runs at just 68 dB — over 10 dB quieter than competitors

2. Water-Lubricated Oil-Free Scroll Compressors

- Revolutionary water lubrication eliminates oil contamination risk

- Integrated refrigerated dryer maintains dew point at -40°C

- 30% smaller footprint, perfect for GMP space constraints

- Maintenance-free design reduces operating costs by 40%

3. Intelligent Compressed Air Management System

- IoT-based remote monitoring platform

- Real-time energy consumption analysis

- Fault warning and diagnosis

- Energy efficiency optimization recommendations

Interactive Demonstrations and Customer Feedback

At the expo, Seize Air featured a Comparison Experience Zone showcasing:

- Real-time energy consumption comparisons between traditional and oil-free compressors

- Compressed air quality tests

- Noise level demonstrations

A technical manager from North China Pharmaceutical praised:

“Seize Air’s oil-free solution surpassed our expectations in cleanliness and energy savings. Their intelligent management system is key to our digital transformation journey.”

Successful Seminar: One-Stop Smart Compressed Air Energy-Saving Solutions

On August 7, Seize Air hosted a well-attended seminar with over 200 professionals. Sales Director Yang Xinpei shared real-world case studies demonstrating how Seize Air’s “equipment + system + service” approach delivers energy optimization through IoT, intelligent algorithms, and professional management.

One case study highlighted:

“For a listed pharmaceutical client, we saved 1.2 million yuan in electricity within a year — achieving 28% energy savings.”

Attendees praised predictive maintenance and real-time energy reports, crucial for factory digitalization and green certifications. The seminar led to 17 companies expressing strong interest, with 5 scheduling factory visits immediately.

Comprehensive Lifecycle Services

Seize Air’s Market Director Zou outlined full-service support:

- Pre-sales: On-site inspections, system design, energy assessments

- During sales: Installation, commissioning, operator training

- After-sales: 30 service centers nationwide, 4-hour emergency response

- Value-added: Energy optimization, equipment leasing, contract energy management

At the exhibition, Seize Air launched its Green Partner Program, offering the first 50 clients:

- Free compressed air efficiency testing

- Three-year extended warranty

- Free intelligent system access

- Annual equipment health checks

Industry Outlook & R&D Innovations

With biotechnology growing fast and “dual carbon” goals pushing sustainability, efficient, clean compressed air will become standard. Seize Air commits to launching a new generation of intelligent oil-free compressors in three years, targeting:

- 20% energy efficiency gains

- 15% noise reduction

Ongoing R&D includes:

- Magnetic levitation oil-free compressors

- AI-powered energy-saving systems

- Advanced nano-filtration materials

About Seize Air Compressors

Seize Air Compressors (Shanghai) Co., Ltd., founded in 2009, is a nationally recognized high-tech enterprise known for its specialization, refinement, and innovation. The company operates a modern production facility spanning 20,000 square meters and houses a national-level energy efficiency laboratory. With over 100 patented technologies, Seize Air holds key certifications including ISO 9001, ISO 14001, as well as international CE and UL certifications. Its products have been successfully exported to more than 30 countries, serving over 1,000 projects in diverse industries such as biopharmaceuticals, food and beverage, electronics, and semiconductors.

Conclusion:

Seize Air is committed to driving innovation and sustainability in the biotechnology industry by delivering cutting-edge, oil-free, and energy-efficient compressed air solutions. As the demand for cleaner and greener production grows, Seize Air will continue to lead the way—empowering businesses worldwide to achieve higher efficiency, lower emissions, and greater operational excellence. Together, we’re building a healthier, more sustainable future for the biofermentation industry and beyond.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch