Introduction

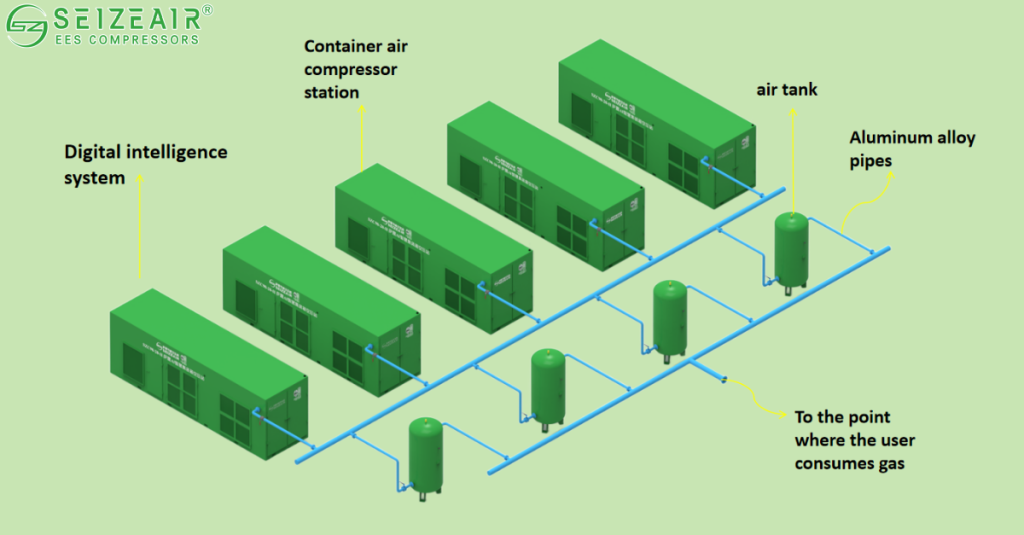

In modern industrial environments, an air compressor station plays a crucial role in ensuring reliable power for production. Yet, traditional systems often struggle with inconsistent pressure and excessive energy consumption. A modular air compressor station solves these issues by integrating multiple compressors with intelligent controls into one efficient network. This setup provides a stable, energy-efficient, and clean air supply — directly addressing the core industrial needs of reliability, cost reduction, and performance consistency.

Enhanced Reliability and Maximum Uptime

One of the greatest strengths of a modular air compressor station is its outstanding reliability. Built-in redundancy ensures that if one unit requires servicing, the remaining modules can continue running without interrupting operations. This design prevents costly downtime and production losses. In addition, advanced control systems continuously track performance data and detect potential faults early. Predictive maintenance based on real-time monitoring ensures consistent uptime and longer equipment lifespan.

Superior Energy Efficiency and Cost Savings

Energy usage represents the largest operational cost for compressed air systems. A modular air compressor station is engineered for high energy efficiency through advanced demand-based control. Instead of operating a single oversized compressor inefficiently, multiple smaller units are automatically sequenced to meet real-time air demand. This smart configuration reduces idle running time, cuts electricity costs, and minimizes environmental impact — contributing to a greener and more sustainable facility.

Modular Design for Flexibility and Scalability

The modular structure offers exceptional adaptability for growing industrial operations. Companies can begin with a base setup and expand capacity easily by adding new compressor modules as production needs increase. This scalable design not only protects initial investment but also shortens installation time — pre-assembled modules can be integrated quickly with minimal disruption to ongoing operations.

Advanced Air Treatment and Quality Assurance

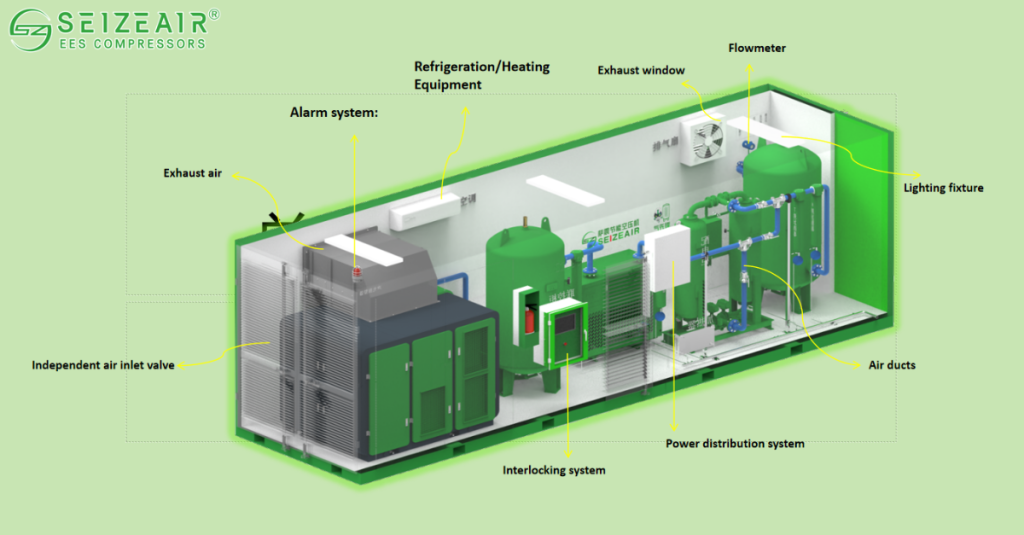

Many manufacturing applications require high-quality compressed air. A complete air compressor station integrates purification components such as dryers, filters, and condensate separators. These elements ensure the delivery of clean, dry, and oil-free air — protecting pneumatic tools and guaranteeing product integrity. Centralized air treatment is also easier to maintain and more efficient than decentralized filtration systems.

Intelligent Control and Remote Monitoring

Modern air compressor stations come equipped with smart control systems that allow real-time monitoring of pressure, flow, temperature, and energy use. Operators can access the system remotely through mobile or desktop interfaces. This connectivity enhances operational transparency, enabling data-driven adjustments for maximum efficiency and faster response to maintenance needs.

Conclusion

Implementing a modular air compressor station is a forward-thinking investment for any industry relying on compressed air. It delivers superior reliability, substantial energy savings, and unmatched flexibility for future expansion. Partnering with an experienced manufacturer like Seize Air ensures long-term value. As a leading Chinese producer of energy-efficient, oil-free screw air compressors, Seize Air supports industries worldwide with durable, high-performance compressed air solutions.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch