Introduction

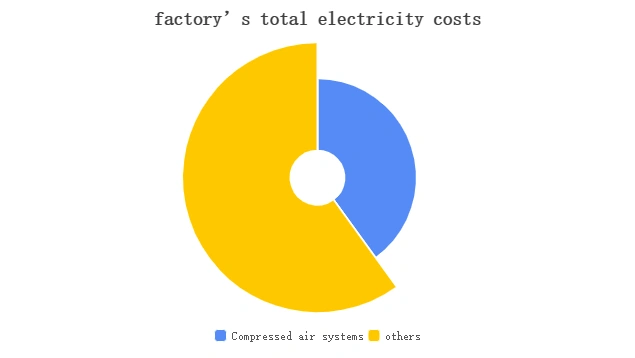

Compressed air systems are a major energy consumer in industrial settings, often accounting for up to 40% of a factory’s total electricity costs. By adopting effective energy-saving methods in air compressor systems, companies can achieve significant cost savings while boosting overall operational efficiency. In this guide, we’ll explore practical strategies that engineers, procurement managers, and facility operators can use to optimize their compressed air systems and achieve meaningful energy savings.

1. Optimizing Compressor Selection and Sizing

1.1 Right-Sizing Equipment

One of the simplest ways to save energy in air compressor systems is by selecting the right equipment size. Using compressors that are too large for the job can result in wasted energy, as they cycle on and off unnecessarily. Conducting a detailed air demand analysis helps identify the optimal compressor size that fits your actual production needs. Keep in mind factors like peak demand, seasonal changes, and future growth when choosing equipment.

1.2 Adopting Advanced Technology

Newer compressor models offer significant energy-saving benefits. Permanent magnet motors, for example, SEIZE AIR maintain high efficiency across varying speeds, unlike traditional motors that lose efficiency at lower loads. Variable Speed Drives (VSD) enable compressors to adjust output to match demand, minimizing energy waste from cycling. When selecting new equipment, prioritize models with built-in energy monitoring features that provide real-time data on power usage and performance.

2. System-Level Optimization Strategies

2.1 Pressure Management and Reduction

For every 1 bar reduction in system pressure, energy consumption drops by about 7%. Many facilities run compressors at higher pressures than necessary, either for safety margins or because of system inefficiencies. Conduct a pressure drop analysis to identify bottlenecks in the distribution system and implement pressure sequencing controls to ensure only the necessary compressors are operating at optimal pressure levels. Regular maintenance of filters and dryers will also help reduce pressure losses.

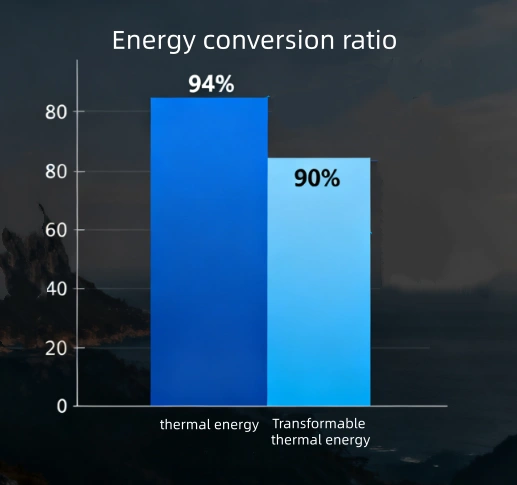

2.2 Implementing Heat Recovery

Compressors turn up to 94% of electrical input into heat, which presents a valuable opportunity for energy recovery. By installing heat recovery systems, you can capture up to 90% of this thermal energy and repurpose it for space heating, process water heating, or other industrial uses. This not only saves energy but also reduces heating costs, making it a highly effective energy-saving strategy.

3. Operational and Maintenance Best Practices

| protection scheme | goal |

| Set up a regular maintenance schedule | includes inspecting air filters, oil filters, and cooler surfaces. |

| Replace filters | Replace filters before pressure differentials reach critical levels |

| ensure proper lubrication | ensure proper lubrication to reduce friction losses and extend the lifespan of the equipment. |

| Establishing a leak management program | routine ultrasonic leak detection surveys, prompt repairs, and employee training can significantly reduce energy waste |

4. Control System Enhancements

4.1 Advanced Control Strategies

Modern compressor control systems provide sophisticated energy management capabilities. Networked controls can optimize multiple compressors across the facility, adjusting operations based on real-time demand patterns. These systems evaluate factors such as efficiency curves, maintenance schedules, and electricity rates to find the most cost-effective operating strategy. For installations with variable demand, smart controls offer one of the best energy-saving solutions.

4.2 Demand-Side Management

Improving energy efficiency doesn’t just happen on the supply side—it also involves managing air consumption at the point of use. Evaluate the efficiency of pneumatic tools and equipment, and replace outdated models with energy-efficient versions. Automatic shut-off valves can prevent unnecessary air use, and employee awareness programs can encourage energy-saving behaviors, such as turning off equipment when not in use.

Conclusion

Adopting effective methods of energy saving in air compressor systems requires a holistic approach that considers equipment selection, operational practices, and maintenance. The strategies outlined in this guide can help industrial facilities achieve substantial energy savings while improving system reliability. Ongoing monitoring and continuous improvement are key to keeping energy performance optimized over the equipment’s lifecycle.

As more industries focus on energy efficiency, companies like Seize Air are developing innovative technologies that incorporate these energy-saving strategies. Their commitment to sustainable solutions plays a critical role in the evolution of energy-efficient compressed air systems.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch