Definition and Core Value of Intelligent Air Compressor

Smart air compressors are devices that integrate Internet of Things (IoT), Artificial Intelligence (AI) and cloud computing technologies to support real-time monitoring, energy efficiency optimization and predictive maintenance. As the core power equipment of Industry 4.0, it reshapes manufacturing through the following features:

- Remote control: mobile phone/computer management of multiple devices, breaking the time and space limitations.

- Energy saving 30%: Inverter technology dynamically matches the load to avoid no-load energy consumption.

- Fault warning: Sensors detect abnormalities (e.g. overheating, leakage) in advance, reducing downtime

Technical rationale and core strengths

Technical architecture

- Sensing layer: Pressure, temperature and vibration sensors collect data in real time.

- Analysis layer: AI algorithm optimizes operating parameters (e.g. speed, exhaust volume).

- Execution layer: automatically adjust the motor or switch the unit to achieve accurate matching of air volume

Three Advantages

| Conventional Air Compressor | Intelligent Air Compressor |

| Fixed speed | Variable frequency speed control, energy saving 30% |

| Manual inspection, failure lag predictive maintenance | Predictive maintenance, reducing downtime by 50% |

| Stand-alone stand-alone operation | Multi-machine joint control, intelligent load distribution |

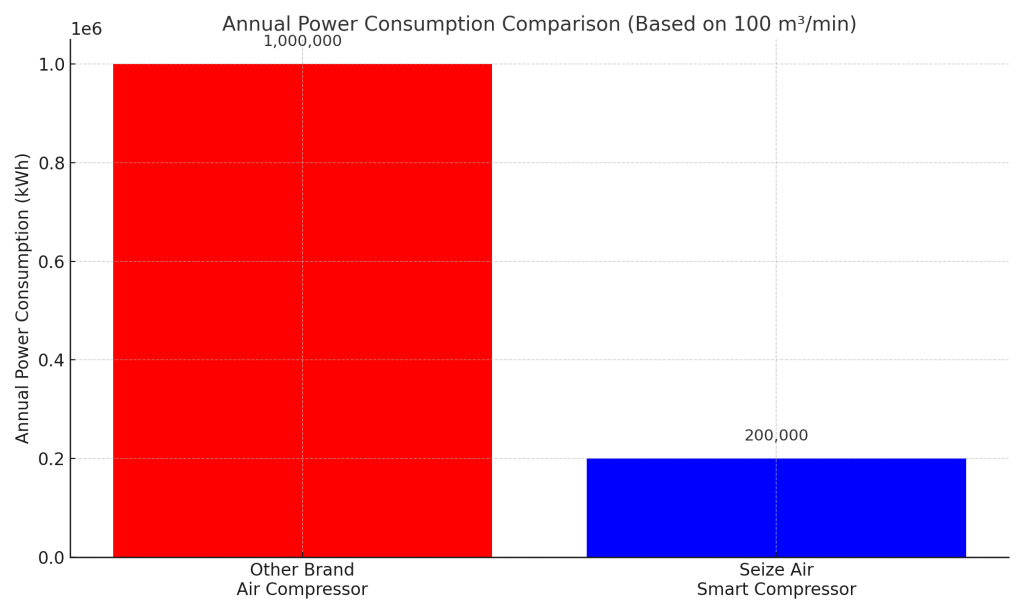

Comparison of Seize Air’s energy-saving air compressor with other brands

| Comparison Dimension | Seize Air Energy Saving Air Compressor | Other mainstream brands (eg. Atl.as Cop.co) |

| Energy efficiency performance | Permanent magnet frequency conversion technology energy saving 30%-50%, than the power industry’s lowest | Energy saving of about 20%-30%, some models rely on imported technology |

| Maintenance Costs | Single maintenance costs $1800, modular design shortens downtime | Maintenance costs $4500, complex maintenance |

| Intelligent function | Support cell phone APP remote monitoring, fault warning for 72 hours | Some models need additional configuration of intelligent module |

| Applicable Scenarios | Covering pharmaceutical, electronics and other industries with high cleanliness requirements | Highly versatile, but with limited high-end customization capabilities |

Application status in the Singapore market

Industry Demand Driven

- Precision Manufacturing: Semiconductors and biomedicals rely on high-clean compressed air (70% of the global market for semiconductor lead welding machines).

- Policy support: Singapore’s Economic Development Board (EDB) subsidizes companies to upgrade high-efficiency equipment, and smart air compressors are included in the Industrial Transformation Index.

Typical Example

A local automotive parts factory went through a smart air compressor:

- Reduced energy consumption by 20%, saving over S$150,000 in annual electricity costs.

- Remote monitoring reduces on-site inspection labor by 75%.

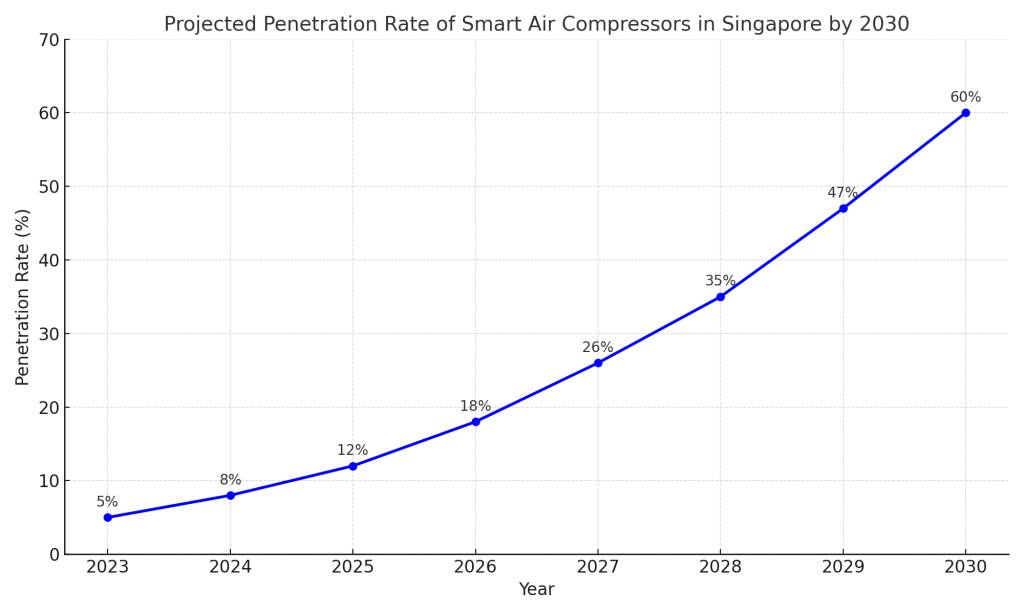

Current status and future trends of air compressor applications in the Singapore market

As a global hub for high-end manufacturing and technological innovation, Singapore’s demand for smart air compressors is growing rapidly. In precision manufacturing areas such as semiconductors and biomedicine, companies require high levels of cleanliness and stability of compressed air, and smart air compressors have become the preferred solution for these industries due to their IoT remote monitoring, variable frequency energy saving and predictive maintenance features. The Singapore government is also actively promoting the transformation of Industry 4.0. The Economic Development Board (EDB) provides subsidies to encourage enterprises to adopt energy-efficient equipment, and smart air compressors are therefore included in the “Industrial Transformation Index” assessment system. For example, a local auto parts manufacturer has successfully reduced its energy consumption by 20% through the deployment of a smart compressor system, saving more than S$150,000 in electricity costs annually, and reducing the need for manual inspections by 75%. In the future, with the advancement of Singapore’s hydrogen energy strategy, hydrogen-powered air compressor technology will become a new development direction, while the introduction of edge computing will further enhance equipment response speed to meet the needs of high-speed intelligent manufacturing.

How enterprises choose and layout of intelligent air compressor

For Singapore enterprises, choosing the right smart air compressor requires comprehensive consideration of industry needs, energy efficiency performance and long-term operation and maintenance costs. In the semiconductor, pharmaceutical and other high-precision manufacturing areas, it is recommended to prioritize the selection of models with oil-free design, high stability and intelligent joint control functions, such as the Sazhen energy-saving air compressor, whose permanent magnet frequency conversion technology can save energy by 30% -50%, and the maintenance cost is significantly lower than that of imported brands. In addition, enterprises should make full use of the Singapore government’s subsidy policy, through the EDB’s energy efficiency upgrade program to reduce the initial investment pressure, and phased replacement of old equipment, and gradually realize the intelligent upgrade of production lines. The ultimate goal is that through the deployment of intelligent air compressors, not only to reduce energy consumption and operation and maintenance costs, but also to improve overall production efficiency, laying a solid foundation for the sustainable development of enterprises.

Intelligent Air Compressors: Opportunities in the Singapore Market and Seize Air‘s Professional Services

With the advancement of Industry 4.0 and green manufacturing, the popularity of smart air compressors is accelerating globally, thanks to their energy efficiency, remote monitoring and predictive maintenance. As a hub for high-end manufacturing and technological innovation, Singapore has a particularly strong demand for smart air compressors, especially in precision manufacturing areas such as semiconductors and biomedicine. Whether it is the Schneider Electric solution that optimizes energy consumption through AI algorithms or the one-stop intelligent control system for Saman air compressors, the industry is moving towards greater efficiency and intelligence.

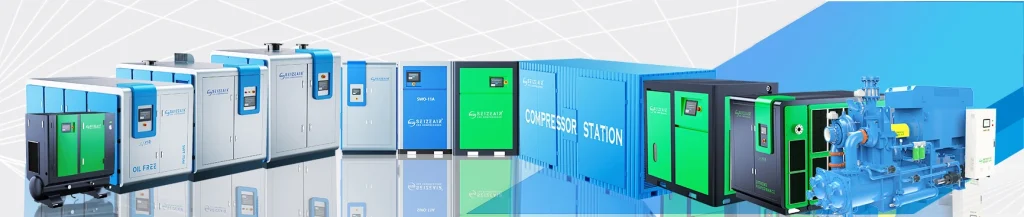

Seize Air, a leading brand in the field of smart air compressors, is committed to providing businesses with a full range of solutions, including:

- Energy-efficient model: adopting permanent magnet frequency conversion technology, it saves more than 30% energy and significantly reduces operating costs.

- Remote monitoring and predictive maintenance: real-time monitoring of equipment status through IoT technology, early warning of failures and reduction of downtime losses.

- Customized service: Provide customized models such as high-pressure, oil-free, etc. for different industry needs (e.g. semiconductor, automobile manufacturing).

- Localized support: Singapore team provides quick response service to ensure stable equipment operation.

If you are looking for a smart air compressor solution or would like to know more about the Singapore government’s energy efficiency subsidy policy, Seize Air is here to provide you with professional consultation and technical support. Contact us today for a free energy efficiency assessment and customized solution!

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch