Introduction

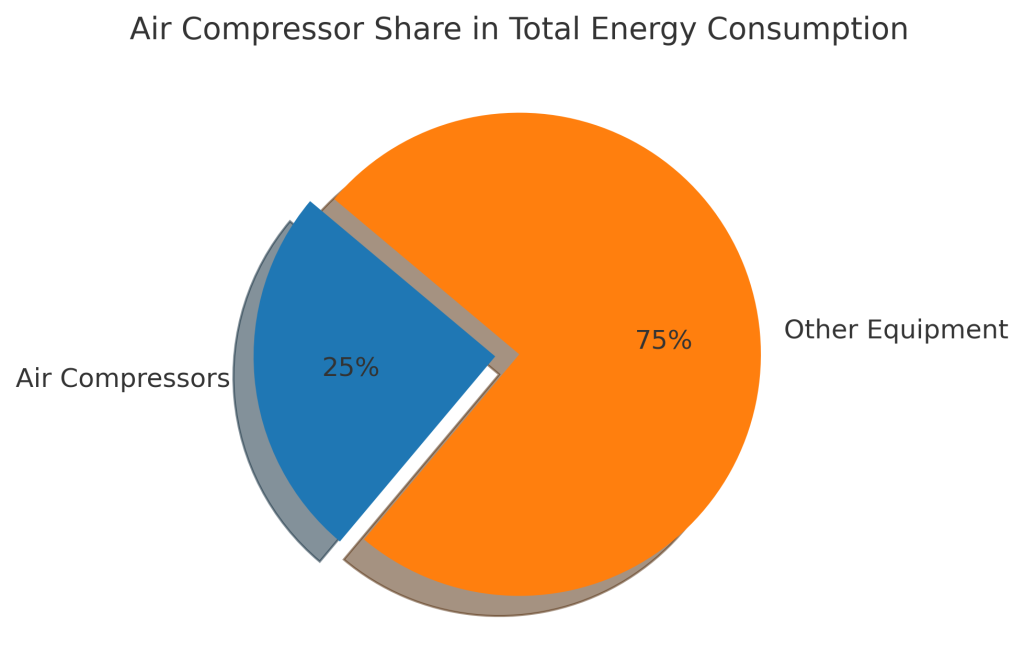

In modern manufacturing, energy saving industrial air compressor systems are vital, as they can account for 20%-30% of total electricity use. With rising energy costs and carbon reduction targets, optimizing these systems is key to cutting expenses and improving efficiency.

As one of China’s leading air compressor brands, Seize Air draws on more than a decade of technical expertise and extensive industry experience to deliver efficient, stable, and energy-saving system solutions for diverse industries.

1. Energy Consumption Analysis of Air Compressor Systems

Main Sources of Energy Consumption

- Compressor main unit: ~60% of total energy use

- Pressure losses: through pipelines, filters, and other components

- No-load operation

- Cooling system power usage

- Air leakage losses: average 20%–30%

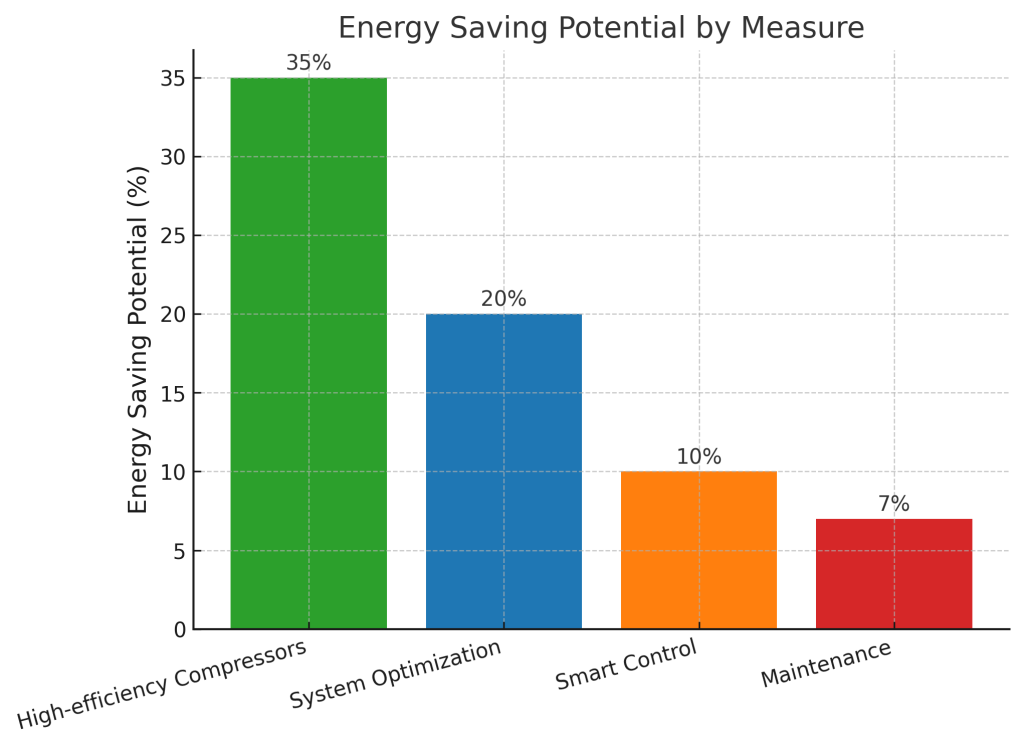

Energy-Saving Potential

- High-efficiency compressors: save 15%–40%

- System optimization: save 10%–25%

- Smart control systems: save 5%–15%

- Maintenance and management: save 5%–10%

2. Seize Air’s Energy-Saving Technology Solutions

2.1 High-Efficiency Main Unit Technology

Seize Air’s permanent magnet variable frequency two-stage compression host features patented rotor profiles and precision machining. Compared with conventional models, it delivers over 30% energy savings.

Technical Highlights

- Patented two-stage compression design reduces recirculation losses

- Precision-machined rotors improve volumetric efficiency by 8%

- Permanent magnet synchronous motor achieves up to 97% efficiency

- Low-speed design extends service life and reduces maintenance costs

2.2 Intelligent Control System

The Seize Air Smart Control system integrates IoT connectivity with advanced algorithms to:

- Control multiple machines and match air output to demand automatically

- Optimize pressure bands to prevent energy waste

- Provide early fault warnings to reduce unplanned downtime

- Continuously analyze and improve system energy efficiency

Case Study: An automotive parts manufacturer saved 850,000 kWh annually after upgrading to Seize Air’s smart control system, achieving a payback period of just 1.2 years.

2.3 Comprehensive System Optimization

- Air source side: Lowering system pressure by 1 bar can cut energy use by about 7%

- Transmission side: Optimize pipeline design to reduce pressure drop by 0.1–0.3 bar

- Air usage side: Detect and repair leaks to avoid waste

- Heat recovery: Capture and reuse up to 80% of compression heat for hot water or heating

3. Seize Air Energy-Saving Product Recommendations

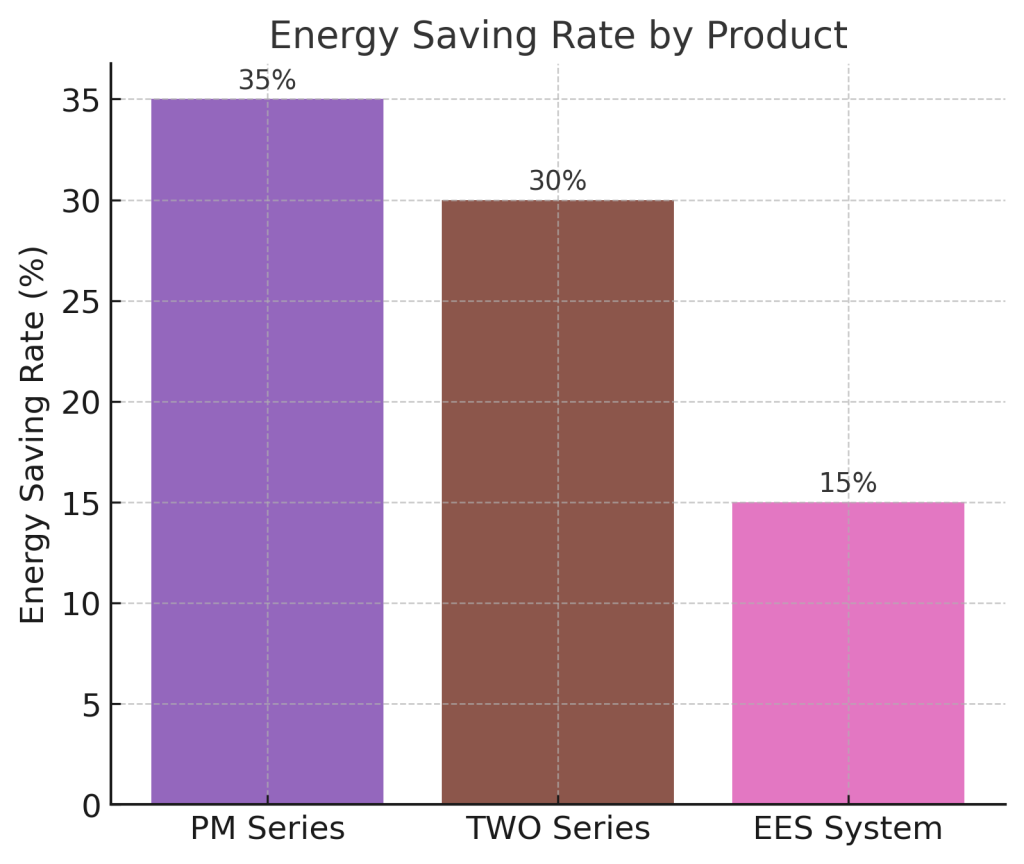

| Product Model | Energy Efficiency Grade | Energy Saving Rate | Key Features | Recommended Applications |

|---|---|---|---|---|

| Permanent Magnet Variable Frequency Compressor | National Level 1 | 30%–40% | Wide frequency range (25–100%), constant pressure supply (±0.01 MPa) | Facilities with large air demand fluctuations |

| Two-Stage Compression Compressor | Super Grade 1 | 25%–35% | Near-isothermal compression, temperature rise reduced by 30°C | Medium to high pressure applications |

| EES Intelligent Energy-Saving System | / | 10%–20% | Real-time monitoring, energy analysis, remote management | Multi-machine control, large industrial plants |

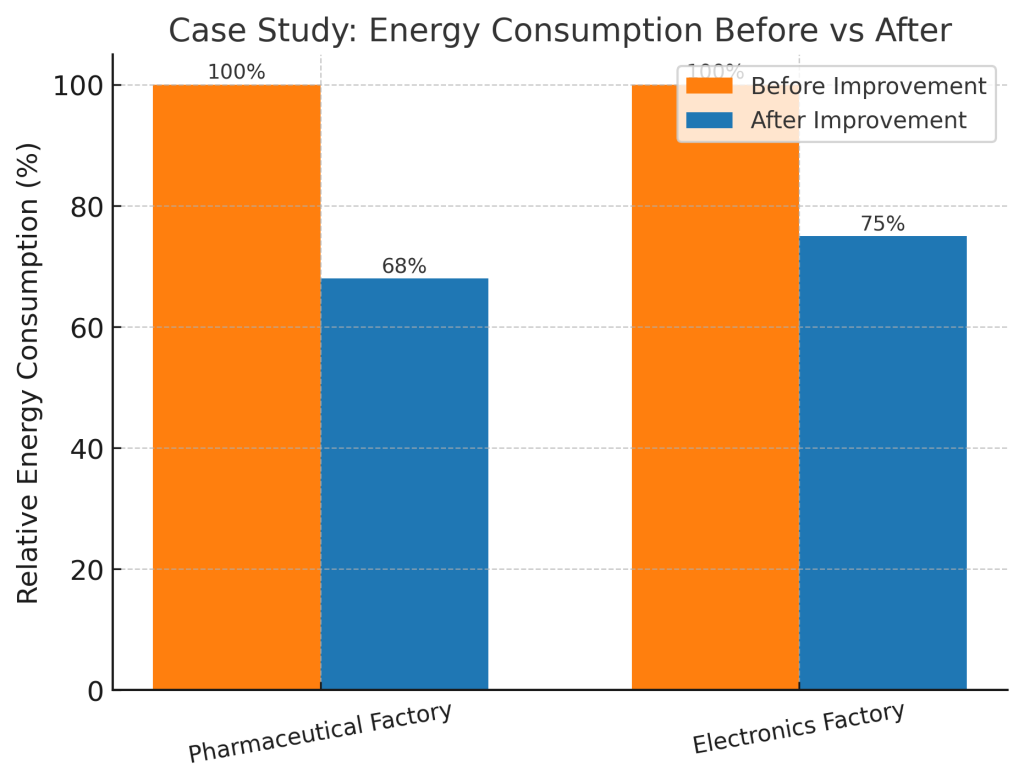

4. Successful Case Studies

Case 1: Pharmaceutical Company Renovation

- Original setup: 3 × 110 kW fixed-speed compressors

- Upgrade: 2 × PM132 permanent magnet variable-speed compressors + EES system

- Result: Annual savings of 580,000 kWh and a 32% energy efficiency improvement

Case 2: Electronics Manufacturing System Optimization

- Issue: Excessive pressure settings and high pressure loss

- Solution: Customized pressure settings + pipeline redesign + smart control system

- Result: 25% energy efficiency increase and annual savings of RMB 460,000 in electricity costs

5. Recommendations for Implementing Energy-Saving Measures

- Audit first: Conduct a full energy efficiency assessment of the compressed air system.

- Implement in stages: Start with the highest-return measures.

- Consider total lifecycle: Balance upfront investment with long-term operational savings.

- Work with professionals: Choose a supplier with strong technical and after-sales capabilities.

Seize Air offers free energy-saving assessments, including:

- Air demand curve mapping

- Leak detection and quantification

- Energy-saving potential evaluation

- Customized upgrade planning

Conclusion

Reducing the energy consumption of air compressor systems is not only about lowering costs — it’s a vital step toward green manufacturing.

Seize Air is committed to providing high-efficiency, reliable, and sustainable solutions for industrial clients worldwide, supporting the achievement of “dual carbon” goals and contributing to a low-carbon future.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch