The textile industry relies heavily on compressed air for textile applications to power critical manufacturing processes, from spinning and weaving to dyeing and finishing. However, many textile manufacturers face challenges with energy consumption and air quality that directly impact product quality and operational costs. SEIZEAIR uses a compressed air system optimized for the production needs of the textile industry, which can significantly improve production efficiency while maintaining the high air purity standards required for textile production.

1. Critical Compressed Air Requirements in Textile Manufacturing

Different textile operations require specific pressure ranges and stable airflow. For example, air jet looms typically operate at 6–8 bar, while spinning frames may perform best at 4–6 bar. Maintaining steady pressure is vital to avoid product inconsistencies and production downtime. Variable frequency drive (VFD) compressors help ensure reliable, consistent pressure across continuous production lines.

2. System Design and Maintenance Best Practices

2.1 Proper Filtration and Air Treatment

Effective air treatment is essential for textile production. Multi-stage filtration—including particulate, coalescing, and activated carbon filters—ensures that air meets industry standards. Regular maintenance prevents pressure drops, saves energy, and keeps air quality high. Automated drain valves and moisture separators protect downstream equipment and prevent water contamination in sensitive processes.

2.2 Pipeline Design and Distribution Optimization

An efficient air distribution system minimizes losses and ensures even air delivery to all machines. Proper pipe sizing, looped layouts, and routine leak detection programs are key. Textile facilities should install drip legs, moisture traps, and strategic shut-off valves to maintain stable, dry, and clean air throughout the production area.

-1024x199.webp)

3. Cost Analysis and Return on Investment

3.1 Lifecycle Cost Considerations

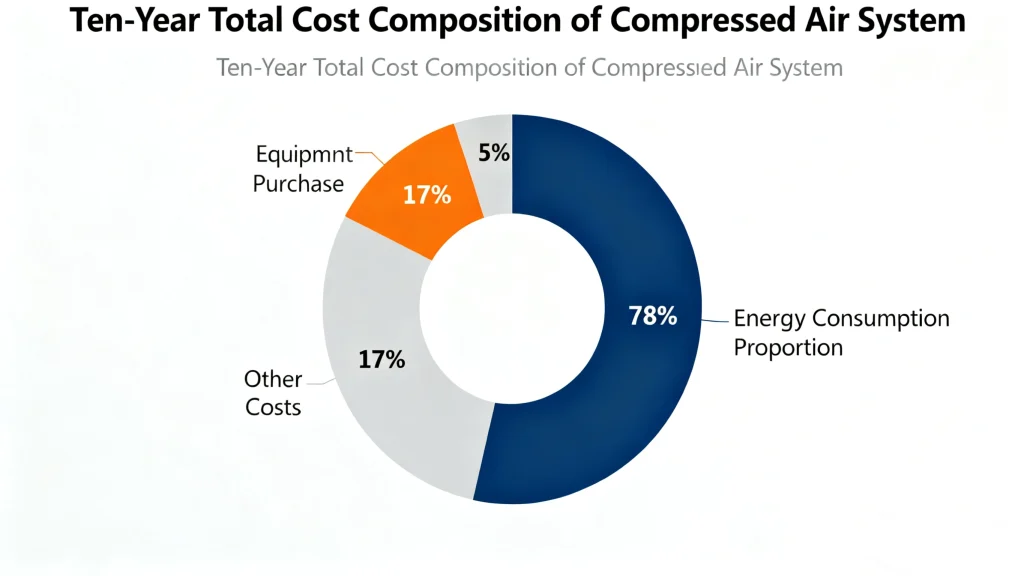

When evaluating compressed air for textile applications, manufacturers should consider total lifecycle costs rather than just initial equipment investment. Energy consumption typically represents 75-80% of total compressed air system costs over a ten-year period. High-efficiency compressors with advanced control systems may have higher upfront costs but deliver significant energy savings that provide rapid return on investment through reduced operating expenses.

3.2 Performance Monitoring and Continuous Improvement

Installing energy monitoring systems helps track air performance and identify optimization opportunities. Key performance indicators include:

- Specific power consumption (kW/m³)

- System efficiency

- Air leak rates

Regular energy audits and continuous improvement initiatives ensure that compressors operate at maximum efficiency throughout their service life.

Conclusion

Optimizing compressed air for textile applications requires careful consideration of air quality, pressure requirements, and energy efficiency specific to textile manufacturing processes. Proper system design, regular maintenance, and advanced control technologies ensure reliable operation while minimizing operational costs. The strategic implementation of compressed air systems directly contributes to textile product quality, manufacturing efficiency, and overall profitability.

Companies specializing in industrial compressed air solutions, such as Seize Air, have developed energy-efficient screw compressors that address the specific requirements of textile manufacturing. Their focus on reliability and energy performance supports textile producers in achieving their production quality and sustainability objectives.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch