The air compressor air tank plays a pivotal role in any compressed air system. It provides storage to ensure consistent pressure delivery, preventing fluctuations that can disrupt operations. Many industrial facilities underestimate the importance of proper tank selection, which can lead to pressure instability, excessive compressor cycling, and reduced energy efficiency. Understanding the functions and proper sizing of receiver tanks can significantly enhance your system’s performance and reduce energy costs.

1. Fundamental Functions of Air Compressor Air Tanks

The air compressor air tank acts as a buffer between the compressor and the air consumption points. During peak demand, the tank supplies stored air to prevent pressure drops. When demand decreases, it stores excess air, reducing the frequency of compressor cycling. This, in turn, improves energy efficiency and extends the life of the compressor by preventing unnecessary starts and stops.

2. Sizing Considerations for Optimal Performance

| Sizing Consideration | Description |

| Calculating Appropriate Tank Capacity | Proper sizing depends on compressor capacity, air demand, and allowable pressure fluctuations. |

| A general guideline: 5-10 gallons per CFM of compressor output. | |

| Systems with varying demand may require larger tanks to maintain pressure stability. | |

| Pressure Rating Requirements | Tank should be rated for pressures exceeding the compressor’s maximum operating pressure. |

| Typical industrial tanks are rated between 150-200 PSI. | |

| Specialized applications may require tanks rated for higher pressures. | |

| ASME certification ensures safety standards and prevents overpressurization risks, while allowing for future system expansion. |

3. Energy Efficiency Implications and Cost Analysis

Reducing Compressor Cycling Costs. Properly sized air compressor air tanks help reduce energy consumption. Each time the compressor starts, a power surge occurs, which can be 3-5 times higher than the running current. Larger tanks reduce the frequency of starts, lowering energy demand. Optimizing tank size can reduce compressor energy usage by 10-15%, especially in systems with fluctuating demand.

4. Information and solutions for SEIZE gas tanks

4.1 Functions of Air Receivers:Air receivers have four main functions:

- Air storage: Stores compressed air and balances system pressure fluctuations

- Pressure stabilization: Stabilizes the output pressure of the compressed air system

- Drainage: Condenses and drains moisture from the compressed air by cooling it

- Prevents frequent compressor starts: Reduces compressor starts and stops, extending equipment life

4.2 Air Receiver Classifications

- Carbon Steel Air Receiver: Model Example: C-2.0/0.8

- Stainless Steel Air Receiver: Model Example: C-2.0/0.8 (Stainless Steel)

- Carbon Steel (Epoxy Coated Interior) Air Receiver: Model Example: C-2.0/0.8 (Epoxy Coated Interior)

4.3 Selection Key Points:When selecting an air receiver for an air compressor system, consider the following parameters:

- Material: Choose carbon steel, stainless steel, or a special material based on the operating environment

- Capacity: Select 20% of the compressor flow rate

- Quantity: Determine based on system requirements

- Pressure: Match the system operating pressure

- Pipe Diameter: Maintain the same diameter as the compressor outlet

Conclusion

The air compressor air tank is more than just a storage vessel. It is a critical component that ensures the stability, efficiency, and safety of the entire system. Proper sizing, installation, and maintenance practices can significantly improve performance, reduce energy costs, and extend equipment life. As air compressor systems evolve, receiver tanks will continue to play a crucial role in balancing air supply and demand.

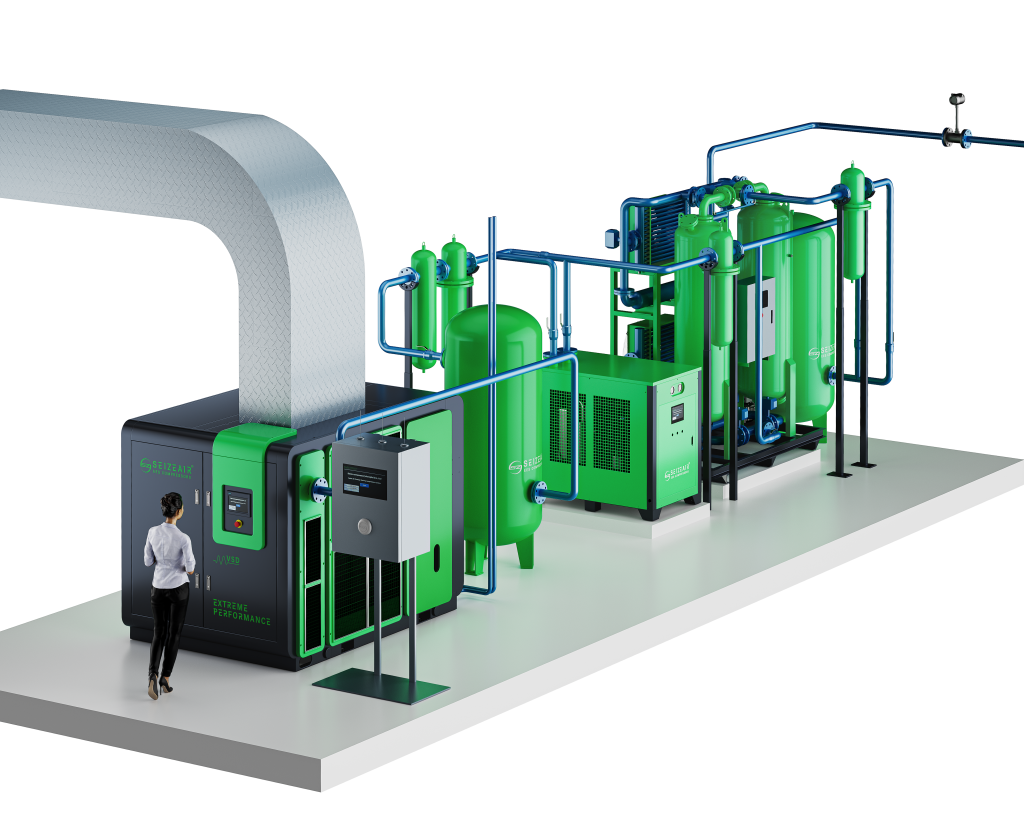

Manufacturers like Seize Air provide optimized solutions with energy-efficient, oil-free screw compressors integrated with properly sized receiver tanks, offering reliable performance and cost-saving benefits in industrial applications.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch