Introduction

Industrial facilities face constant pressure to optimize compressed air systems. The screw compressor offers a superior solution for demanding applications. Its unique design addresses common pain points effectively. This technology delivers reliability and efficiency simultaneously.

1. Superior Efficiency

Modern screw compressor designs achieve remarkable energy efficiency. Variable speed drives match output to demand precisely. This eliminates wasteful energy consumption during low-load periods. Studies show rotary screw compressors save 15-30% energy versus alternatives. The twin screw design maintains consistent pressure without fluctuations. Industrial users report significant electricity cost reductions annually.

2. Exceptional Reliability and Durability

Industrial environments demand equipment that withstands continuous operation. The screw compressor operates with minimal vibration and noise. Its simple design has fewer moving parts than piston compressors. This translates to reduced wear and extended service life. Many units operate reliably for over 50,000 hours before major servicing. Manufacturing facilities benefit from uninterrupted production cycles.

3. Low Maintenance Requirements

Maintenance downtime costs factories substantial productivity losses. The screw compressor requires less frequent servicing than alternatives. Oil-flooded models can operate 8,000 hours between oil changes. Modern filtration systems protect internal components effectively. Predictive maintenance technologies alert technicians before issues arise. This proactive approach prevents unexpected breakdowns completely.

4. Versatility Across Industrial Applications

Different industries have unique compressed air requirements. The screw type air compressor adapts to diverse applications seamlessly. Food processing needs oil-free air certification capabilities. Automotive manufacturing demands consistent high-volume output. Pharmaceutical applications require sterile air quality standards. Textile plants utilize specific humidity control features.

5. Advanced Technological Features

Today’s industrial screw compressor incorporates smart technologies. IoT connectivity enables remote monitoring and control. Real-time data analytics optimize performance continuously. Automated systems adjust operations based on usage patterns. These features reduce manual oversight requirements significantly. They provide valuable operational insights for decision-makers.

6. Cost-Effectiveness Over Equipment Lifespan

While initial investment may be higher, lifetime costs are lower. Energy savings typically recover price differentials within two years. Reduced maintenance expenses contribute to long-term savings. Higher reliability prevents production loss from air system failures. These financial advantages make screw compressors economically smart choices.

7. Environmental Compliance and Sustainability

Modern manufacturing must meet increasingly strict environmental standards. Oil-free screw compressors eliminate hydrocarbon contamination risks. Advanced sound insulation reduces noise pollution in workplaces. Energy-efficient models lower carbon footprints substantially. Companies demonstrating environmental responsibility enhance their market positions.

Conclusion

The screw compressor represents the optimal choice for industrial applications. Its combination of efficiency, reliability, and low maintenance delivers unmatched value. Technological advancements continue to enhance performance capabilities. Environmental benefits align with sustainable manufacturing initiatives.

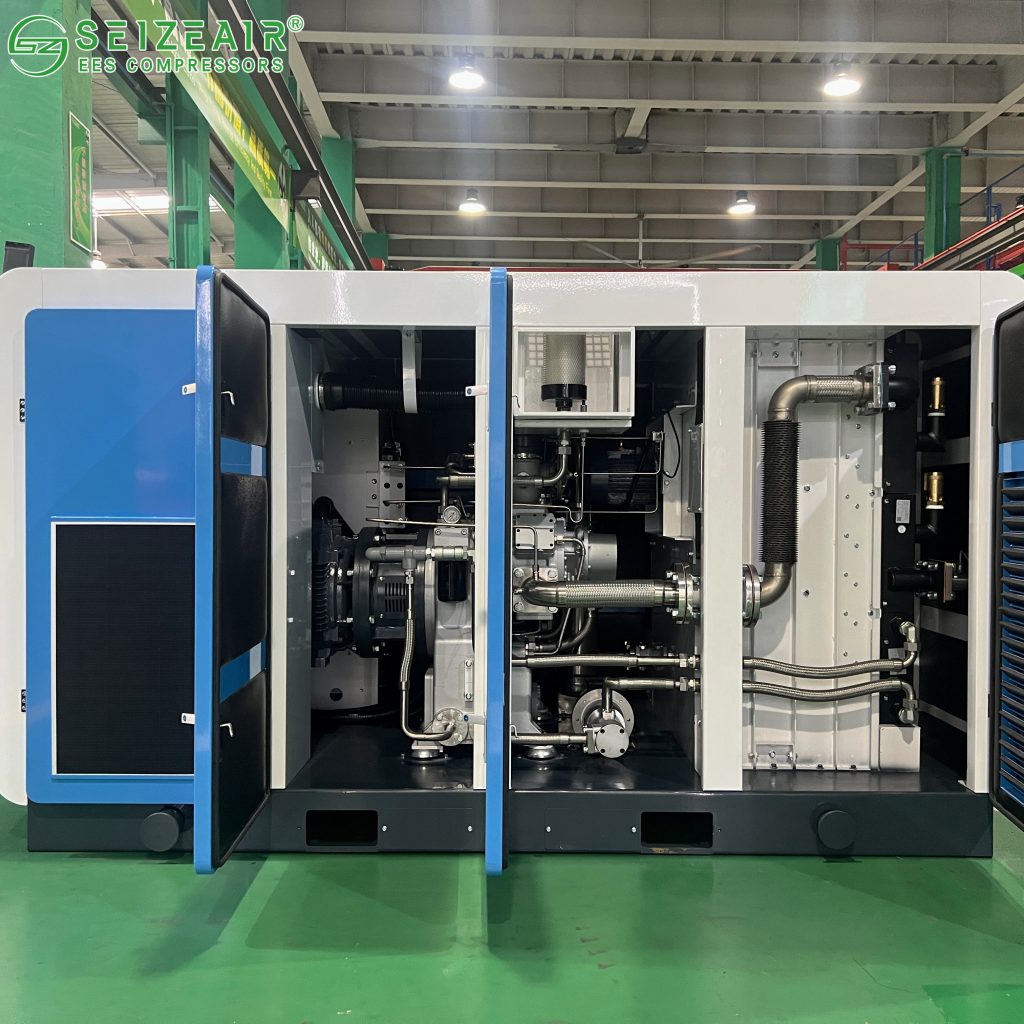

Companies like Seize Air develop advanced screw compressor technologies. Their energy-efficient designs meet diverse industrial requirements effectively. Such manufacturers combine innovation with practical application knowledge. They support global industrial productivity with reliable solutions.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch