Introduction

In today’s industrial landscape, energy costs account for a significant portion of operational expenses, with traditional air compressors often being a hidden culprit. Known as “electricity tigers,” these machines can consume excessive power, driving up costs unnecessarily. The solution? Energy saving air compressors—advanced systems designed to reduce electricity consumption by 20–30% while maintaining high performance. This article explores the technology, benefits, and selection criteria for these compressors, helping procurement managers and engineers make informed decisions.

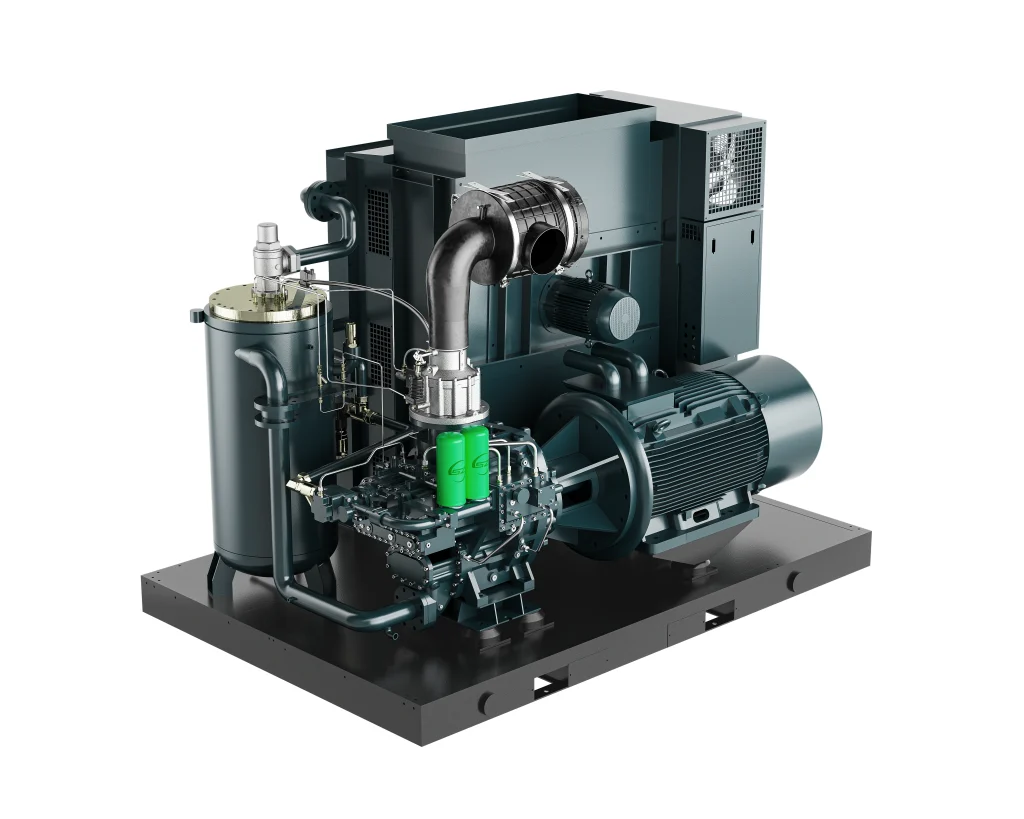

1. How Energy Saving Air Compressors Work

Core Technologies

- High-Efficiency Low-Speed Two Stage Screw Airend:Isothermal Compression Principle,higher volumetric efficiency,Low Compression Ration

- Permanent Magnet Premium Efficiency Motor: IE4-class PM motor delivers 98% efficiency with 5% energy saving over standard VFD motors

- Wide Speed Range with Precise Control:Broad adjustable speed range (25%–100%) with ±0.5% pressure precision for stable operation

- Oversized Cooling System: 30% larger radiator with anti-corrosion nano-coating (salt spray test >1000h),Quick-release dustproof mesh,15% better heat dissipation than industry average

- Smart Controls: IoT-enabled systems monitor pressure, temperature, and load in real-time, optimizing output while preventing malfunctions.

2. Key Advantages for Industrial Applications

2.1 Unmatched Efficiency

- Pressure Customization: Tailored pressure settings (e.g., 0.2–1.25MPa) ensure no energy is wasted on unnecessary output.

- Reduced Heat Loss: Advanced cooling systems (e.g., oversized radiators) maintain stable temperatures even in 52°C environments, preventing downtime.

2.2 Reliability and Durability

- High-Quality Components: SKF bearings, stainless steel rotors, and Donaldson air filters extend lifespan and reduce maintenance.

- Low Noise Operation: Designs like centrifugal fans and isolated intake systems keep noise levels below 78dB.

2.3 Industry-Specific Solutions

- Oil-Free Models: Ideal for pharmaceuticals and food processing

- Low-Pressure Variants: For textiles and laser cutting, offering 10–130 m³/min flow rates at 0.2–0.45MPa.

3. Choosing the Right Energy Saving Air Compressor

3.1 Assess Your Needs

- Flow Rate & Pressure: Match specifications to your highest demand scenarios.

- Duty Cycle: Opt for VFD models if load fluctuates frequently.

3.2 Evaluate Long-Term Costs

- Lifecycle Savings: A 20% reduction in energy use can save $300,000+ over 10 years for a 250KW unit.

- Maintenance: Look for features like self-cleaning filters and predictive maintenance alerts.

3.3 Verify Certifications

- Check for IE4/IE5 motor efficiency and compliance with API 672/613 standards for centrifugal models.

Conclusion

Energy saving air compressors are no longer a luxury but a necessity for industries aiming to cut costs and meet sustainability goals. With technologies like dual-stage compression, VFD motors, and smart controls, these systems deliver tangible ROI while reducing carbon footprints.

For reliable solutions, consider Seize Air, a Chinese manufacturer specializing in energy-efficient oil-free screw compressors, such as the SVC series, combine innovation with practicality, ensuring performance without compromise.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch