Air Compressors: The “Fourth Industrial Energy Source”

Air compressors have become essential to global manufacturing, often referred to as the “fourth largest source of industrial energy.” In fact, they account for up to 25% of electricity consumption in manufacturing, and their operating costs can exceed 80% of a factory’s total energy expenses. As a core power system, air compressors are widely used across automotive, electronics, pharmaceuticals, metallurgy, food processing, and other key industries—playing a crucial role in maintaining productivity and ensuring process integrity.

As countries pursue carbon neutrality goals and embrace Industry 4.0 transformation, the traditional air compressor is evolving into a smart, green, and energy-efficient solution—becoming a strategic asset for quality improvement and cost reduction in manufacturing.

Three Core Functions of Industrial Air Compressors

1. Power Supply for Pneumatic Systems

Air compressors power a wide range of pneumatic tools (e.g., spray guns, wrenches) and automation equipment (e.g., cylinders in assembly lines), replacing traditional electric motors. This not only increases safety in harsh environments but also enhances production flexibility.

2. Process Reliability and Clean Air Support

Modern industries such as semiconductors, pharmaceuticals, and food processing demand high-purity, oil-free compressed air. Air compressors enable processes like aseptic packaging and microelectronic manufacturing by ensuring clean, stable air pressure, thereby reducing contamination risks and improving product quality.

3. Energy Savings and Environmental Benefits

With technologies like variable speed drives (VSD) and heat recovery systems, air compressors can reduce energy consumption by 30–50% and reuse up to 90% of waste heat, supporting sustainable manufacturing and lowering carbon emissions.

Air Compressors: The Invisible Engine Behind High-Efficiency Manufacturing

In sectors like automotive painting, electronics packaging, and high-speed food filling lines, air compressors play a key role in improving both output speed and product quality. For instance, food packaging lines powered by compressed air can reach speeds of 1,200 packs per minute, while semiconductor yields increase due to contamination-free environments.

This cross-industry value makes air compressors the “invisible engine” that drives modern manufacturing efficiency and precision

Evolving Demands: From Power Equipment to Smart Manufacturing Infrastructure

1. Diverse and Specialized Industry Needs

Air compressor demand is shifting from general-purpose models to highly specialized, efficient systems tailored to specific industries:

- Automotive: Uniform air pressure for flawless painting.

- Electronics: Class 0 oil-free air for ultra-clean environments.

- Pharmaceuticals & Food: GMP-compliant clean air for sterile production.

2. Energy Efficiency and Smart Technology Integration

Modern manufacturing prioritizes energy-efficient and intelligent solutions:

- Permanent Magnet Variable Speed Drives (PMVSD): Save 30–50% energy.

- IoT-Enabled Monitoring: Real-time performance tracking reduces downtime by up to 30%.

- AI-Powered Predictive Maintenance: Minimizes failures and maintenance costs.

3. Customized Solutions for Emerging Sectors

Rapid growth in new energy, lithium battery, hydrogen storage, and semiconductor industries is driving demand for high-pressure, explosion-proof, oil-free air compressor solutions. Meanwhile, the replacement of over 500,000 outdated screw compressors in China alone presents a vast market opportunity.

Global Industry Outlook and Key Trends

The air compressor industry is entering a new phase of global competitiveness and technological innovation, with key trends including:

1. Breakthroughs in High-End Manufacturing

Localized production of high-tech components—like magnetic bearings, oil-free modules, and hydrogen energy compressors—reduces reliance on imports and enhances supply chain resilience.

2. Green and Digital Transformation

Integration of next-gen technologies:

- IE5 permanent magnet motors

- Heat recovery systems (90%+ efficiency)

- AI & IoT for predictive maintenance and cluster control

3. Service-Oriented Business Models

New models such as:

- Energy Management Contracts (EMC)

- Compressed Air as a Service

- Data-driven operations & maintenance (O&M)

4. Growth in Emerging Applications

Booming demand from:

- Hydrogen energy storage

- Semiconductor fabs (Class 0 air)

- Medical oxygen production (15%+ annual growth)

By 2030, the global air compressor market is expected to reach USD 51.8 billion, growing at a 5.2% CAGR, with China, India, Southeast Asia, and the Middle East driving the majority of this expansion.

Seize Air: Leading the Global Shift to Energy-Saving Air Compressors

Founded in 2009 and headquartered in Shanghai’s Jinshan Industrial Zone, Seize Compressor (Shanghai) Co., Ltd. is a national high-tech enterprise specializing in the R&D, manufacturing, and global distribution of energy-efficient air compressors.

Seize Air in Numbers:

- 500+ employees

- 200+ global service outlets

- 30,000+ units sold

- 3 million+ kW installed power

- ¥15 billion+ electricity cost saved for clients

- 15 million tons of carbon emissions reduced

This is equivalent to planting 830 million trees.

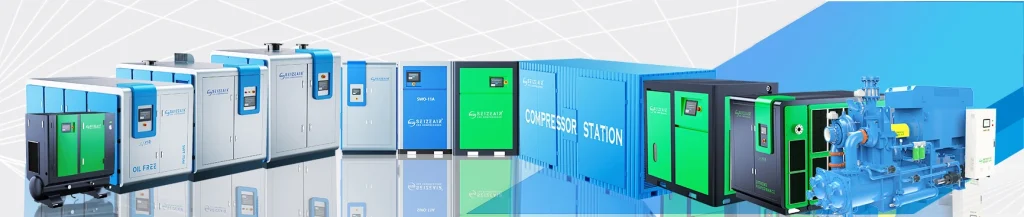

Product Portfolio:

- Permanent Magnet Variable Speed Compressors

- Oil-Free Screw Compressors (ISO 8573-1 Class 0 certified)

- Centrifugal Compressors

- Customized solutions for textile, lithium battery, medical, and food industries

Core Technologies and Competitive Advantages

Energy Efficiency

Dual-stage compression + PM motor

Pressure ratio optimization: 12–15% more efficient than standard models

Seize Air Cloud IoT system: ±0.1 bar pressure stability, saving 30–45% energy annually

Oil-Free Purity

Class 0 certified dry screw technology

<2ppm oil content ensures compliance in pharma, electronics, and food sectors

Industry Customization

Noise-optimized compressors for textiles (≤65 dB)

Lithium battery sector-specific oil-free solutions

Global Strategy & Service Commitment

Seize Air has successfully broken the monopoly of foreign brands (e.g., Atlas Copco, Ingersoll Rand) in China’s textile and chemical sectors, with major clients including CATL and BYD. The company is certified as a “National Energy Efficiency Star” (Certificate No. 001) and has exceeded China’s Grade 1 energy-efficiency standards.

Products have been exported to 20+ countries including Southeast Asia, India, and Turkey, with plans to expand into Europe and North America.

Global Service Highlights:

Predictive maintenance using IoT early warnings

.

24/7 hotline and 2-hour response time

99% issue resolution rate within 24 hours

Global parts reserve and lifetime maintenance support

Conclusion: Powering the Future of Green and Smart Manufacturing

As the global manufacturing landscape transforms, Seize Air is at the forefront—providing reliable, energy-efficient, and intelligent air compressor solutions. With its vision of “respecting the sky and loving people,” Seize Air empowers industries to achieve cost savings, efficiency, and sustainability, shaping a greener future for global manufacturing.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch