When investing in a reliable air compressor for sensitive applications, selecting the right type of oil-free screw compressor is essential. Two of the most common types are dry oil-free screw compressors and water-lubricated screw type compressors. Each comes with its own advantages and limitations depending on the industry, operating environment, and performance expectations.

In this guide, we break down the key differences, pros and cons, and help you understand how Seize Air can support your decision with advanced compressor solutions.

Understanding Oil-Free vs. Oil-Injected Compressors

Before diving into dry vs. water-lubricated types, it’s important to distinguish between oil-free vs. oil-injected compressors:

- Oil-injected screw compressors use oil for lubrication, cooling, and sealing. While highly efficient and durable, they require complex filtration systems to remove oil contaminants from compressed air.

- Oil-free screw compressors, in contrast, do not introduce oil into the compression chamber. This makes them ideal for industries like pharmaceuticals, electronics, food and beverage, and healthcare — where air purity is critical.

What Are Dry Oil-Free Screw Compressors?

Dry oil-free screw compressors operate without any liquid lubricants inside the compression chamber. Instead, they rely on precision-engineered rotors and coatings to reduce friction.

✅ Pros of Dry Oil-Free Compressors:

- No risk of water contamination, making them suitable for moisture-sensitive environments.

- Simpler internal design leads to fewer parts in contact with the compressed air stream.

- Ideal for low to moderate duty cycles where intermittent operation is common.

❌ Cons of Dry Oil-Free Compressors:

- Lower energy efficiency compared to lubricated types.

- Higher noise levels due to metal-to-metal contact.

- Reduced cooling efficiency, which may lead to higher operating temperatures.

What Are Water-Lubricated Screw Type Compressors?

Water-lubricated screw compressors use purified water to lubricate, seal, and cool the compression process. They are a subcategory of oil-free compressors and have gained popularity in recent years due to their high efficiency and eco-friendliness.

✅ Pros of Water-Lubricated Compressors:

- Superior cooling and sealing, resulting in higher efficiency and lower energy costs.

- Extremely quiet operation, ideal for indoor and noise-sensitive environments.

- Environmentally friendly, since no oil or hazardous substances are involved.

- Lower maintenance costs due to reduced wear and thermal stress.

❌ Cons of Water-Lubricated Compressors:

- Requires water treatment and filtration to maintain system purity and prevent scaling.

- May not perform well in freezing environments without added precautions.

- More complex water management systems compared to dry types.

Dry vs. Water-Lubricated: Which Should You Choose?

The decision between dry and water-lubricated screw type compressors depends largely on your application:

| Criteria | Dry Oil-Free Compressor | Water-Lubricated Screw Compressor |

|---|---|---|

| Air Purity Requirements | High | Ultra-high |

| Energy Efficiency | Moderate | High |

| Noise Level | Higher | Lower |

| Maintenance Complexity | Lower | Moderate (due to water systems) |

| Operating Conditions | Versatile | Needs temperature-controlled space |

| Eco-Friendliness | Good | Excellent |

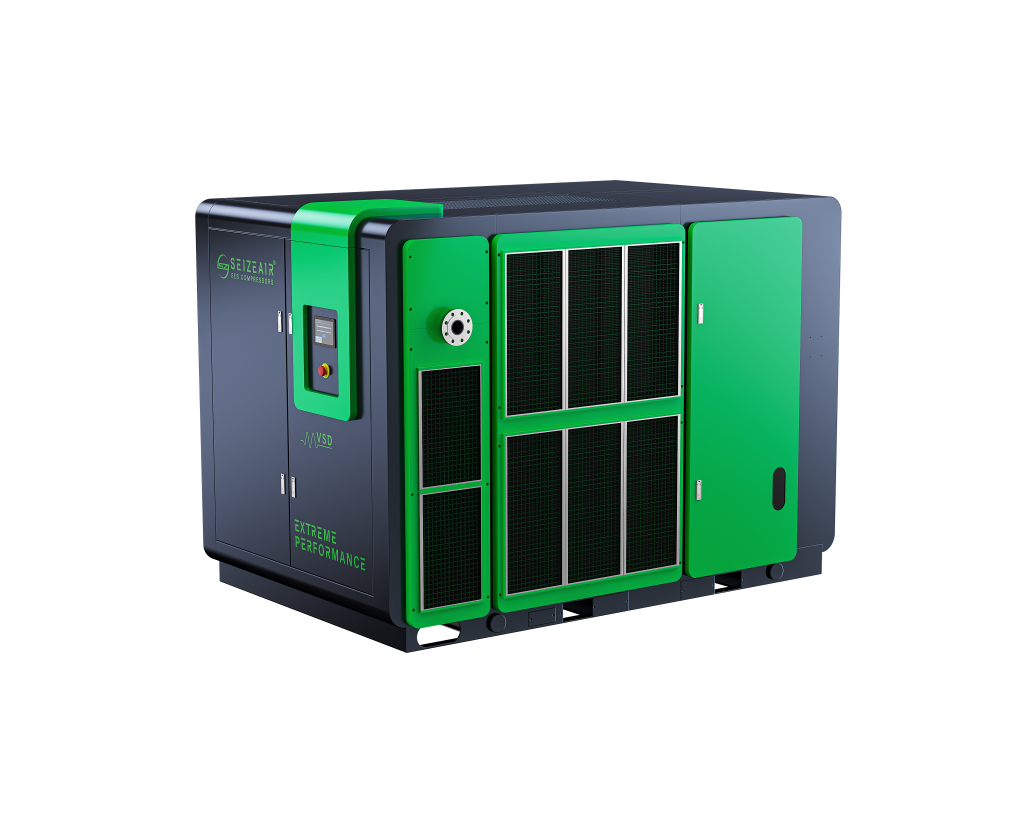

Why Choose Seize Air?

At Seize Air, we specialize in both dry and water-lubricated screw type oil-free compressors, engineered to deliver unmatched performance, energy savings, and long-term reliability. Our expert team helps businesses choose the most suitable model based on their operating conditions, industry standards, and sustainability goals.

Whether you’re transitioning from oil-injected compressors to a cleaner alternative, or upgrading your existing system for greater efficiency, Seize Air is your trusted partner.

Conclusion

When comparing oil-free vs. oil-injected compressors, or deciding between dry and water-lubricated screw compressors, consider the full picture: application requirements, environmental conditions, and long-term operational costs. Water-lubricated systems offer excellent performance for high-purity industries, while dry compressors remain a solid choice for simpler, lower-load scenarios.

For tailored advice and high-performance solutions, contact Seize Air today — your source manufacturer for next-generation compressed air systems.

English

English

Français

Français

Español

Español

Português

Português

Deutsch

Deutsch